ExoMars 2022

Non-EO

ESA

NASA

Planned

Quick facts

Overview

| Mission type | Non-EO |

| Agency | ESA, NASA |

| Mission status | Planned |

ExoMars 2022 Mission (formerly ExoMars 2020)

Concept Launch Development Status Payloads References

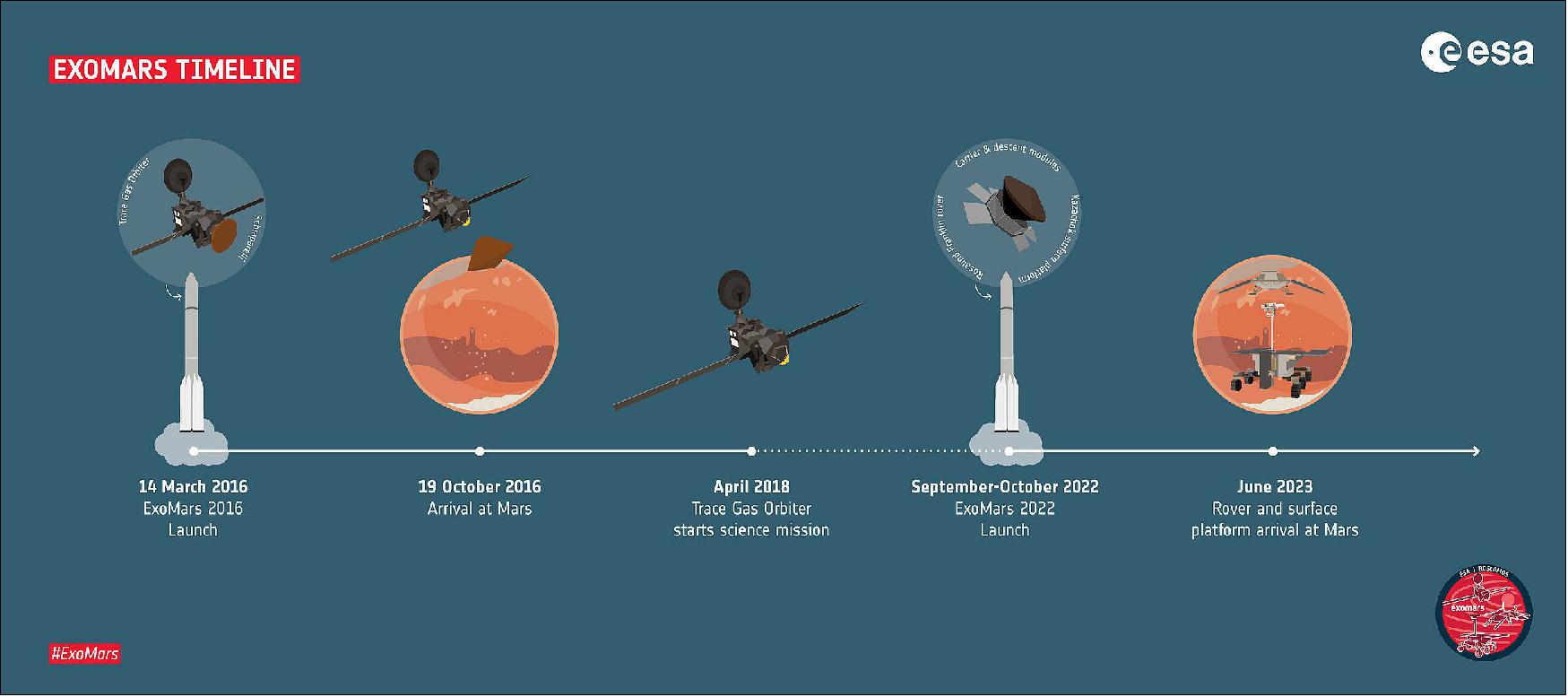

The ExoMars program, consisting of two missions, is the first step of ESA's Aurora Exploration Program and is developed in a broad ESA and Roscosmos cooperation, with a contribution from NASA in the areas of Mars proximity Communications and the scientific payloads. It addresses the scientific question of whether life ever existed on Mars and will demonstrate key technologies for entry, descent, landing, drilling and roving on the Martian surface. 1) 2)

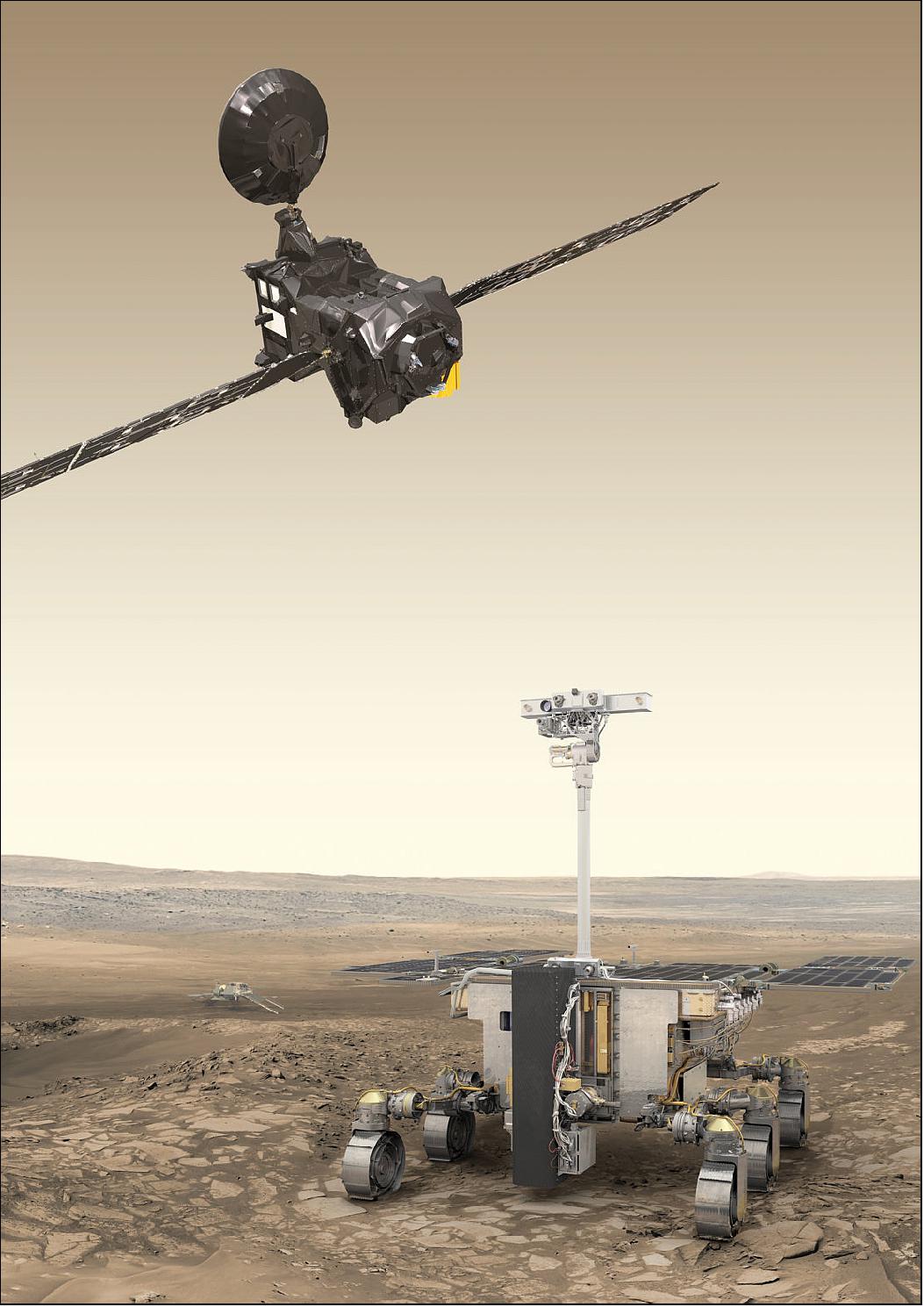

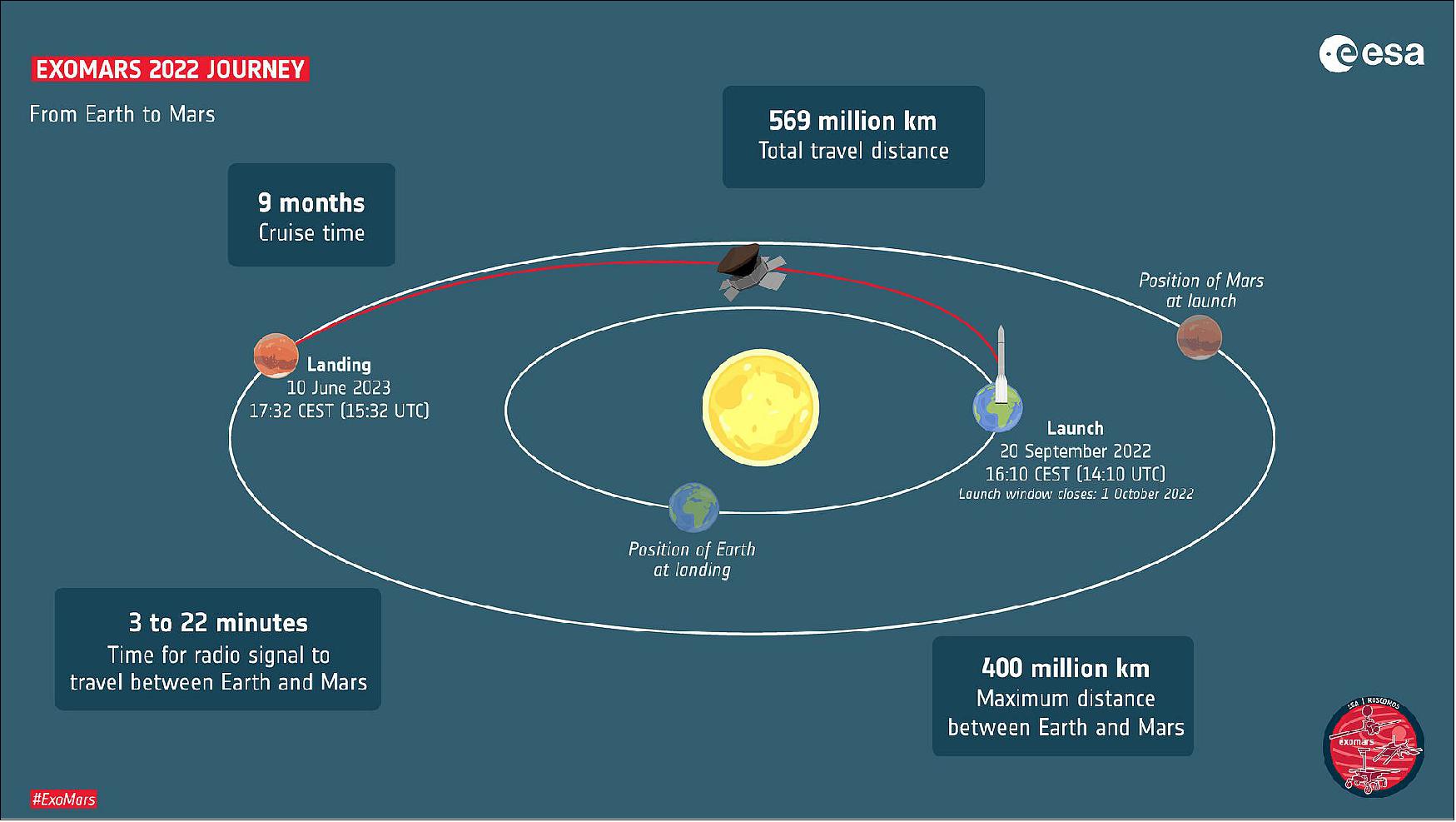

The 2020 mission of the ExoMars program will deliver a European rover and a Russian surface platform to the surface of Mars. A Proton rocket will be used to launch the mission, which will arrive to Mars after a nine-month journey. The ExoMars rover will travel across the Martian surface to search for signs of life. It will collect samples with a drill and analyse them with next-generation instruments. ExoMars will be the first mission to combine the capability to move across the surface and to study Mars at depth. 3)

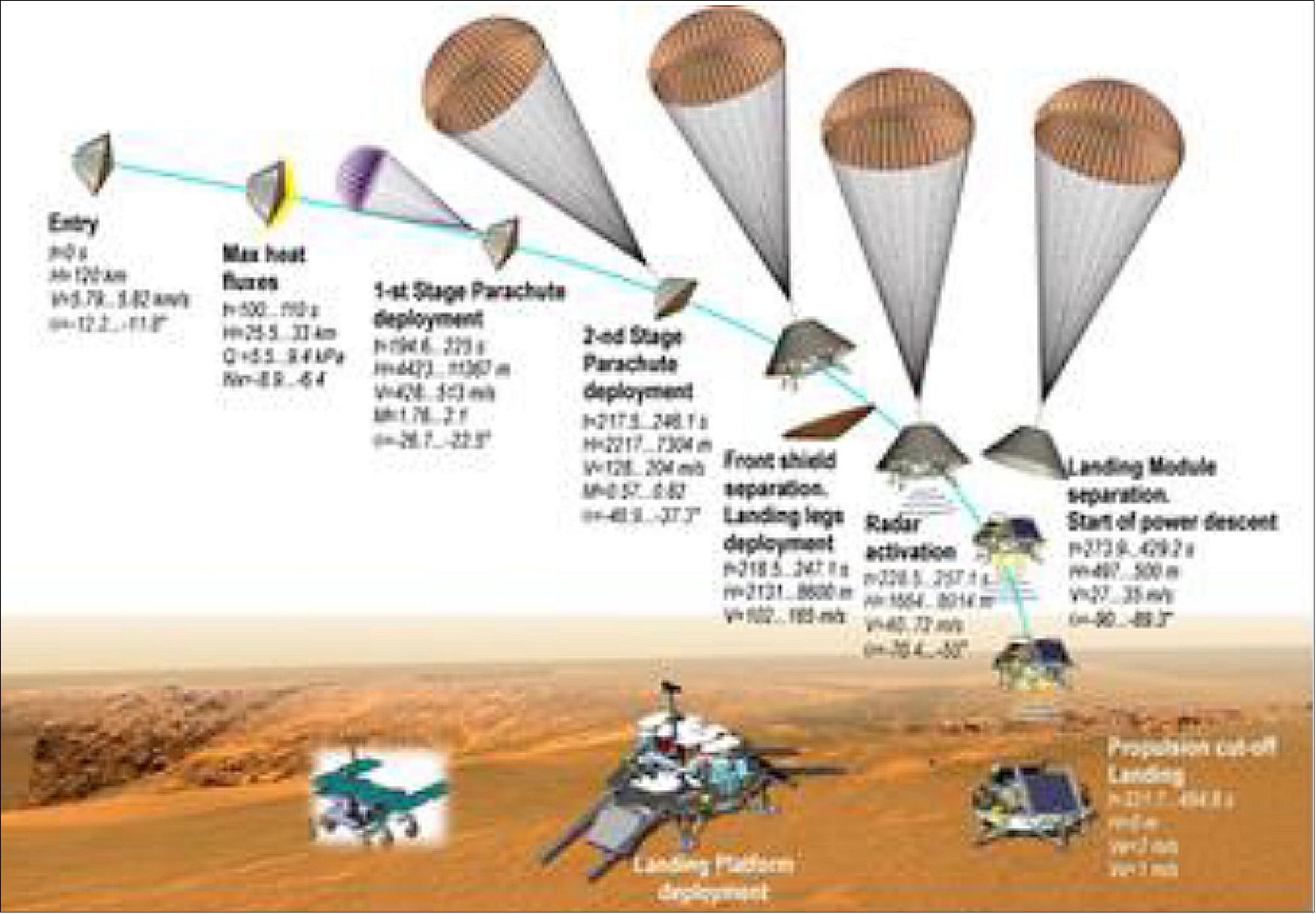

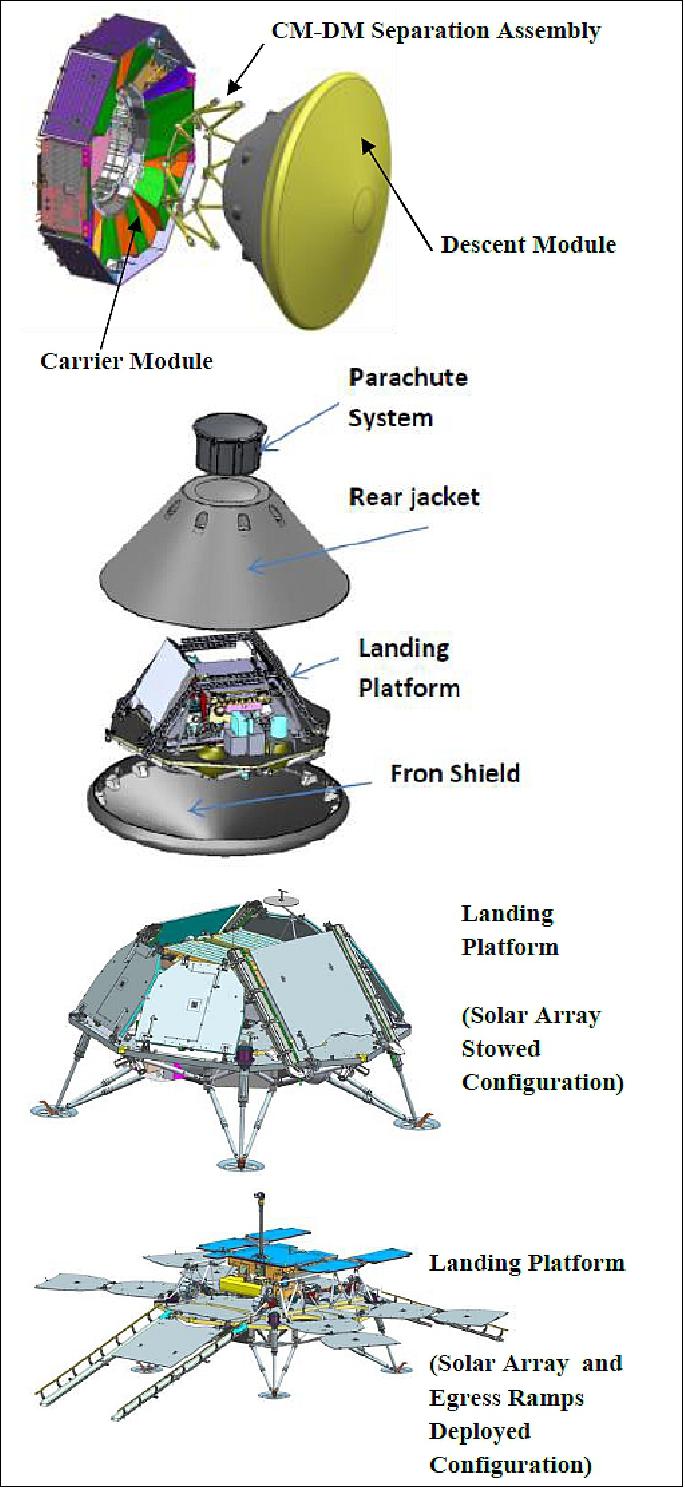

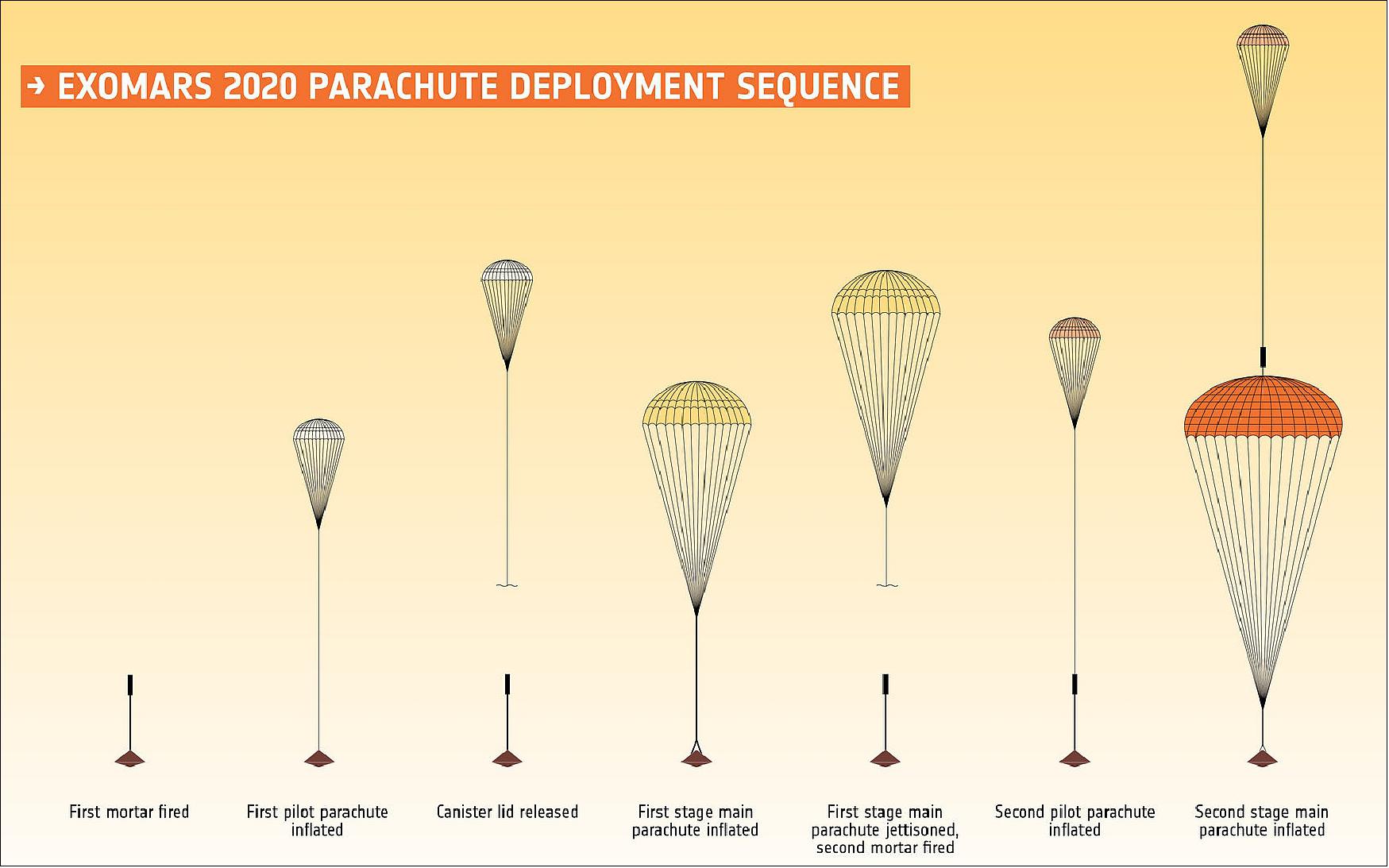

During launch and cruise phase, a carrier module (provided by ESA) will transport the surface platform and the rover within a single aeroshell. A descent module (provided by Roscosmos with some contributions by ESA) will separate from the carrier shortly before reaching the Martian atmosphere. During the descent phase, a heat shield will protect the payload from the severe heat flux. Parachutes, thrusters, and damping systems will reduce the speed, allowing a controlled landing on the surface of Mars.

The ExoMARS 2020 Program will secure the development and qualification of the following technologies:

• Entry, Descent and Landing (EDL) of a payload on the surface of Mars

• Surface mobility with a Rover

• Access to the sub-surface to acquire and analyze in-situ Mars terrain samples

• Qualification of Russian ground-based means for deep-space communication in cooperation with ESA’s ESTRACK

• Adaptation of Russian on-board computer for deep space missions and ExoMars landed operations

• Development and qualification of throttleable braking engines for prospective planetary landing missions.

The above activities will be carried out in accordance with the ESA Policy on Planetary Protection, which complies with the COSPAR planetary protection recommendations.

The ExoMars Program scientific objectives are to:

• Search for signs of past and present life on Mars

• Investigate the water/geochemical environment as a function of depth in the shallow subsurface

• Investigate Martian atmospheric trace gases and their sources

• Investigate and solve scientific problems within the composition of Mars Surface long-living stationary platform.

A further objective of the ExoMars Program is to provide data relay services, through the TGO (Trace Gas Orbiter), for landed assets on the surface of Mars until the end of 2022.

All these objectives will be pursued as part of a broad international cooperation with Roscosmos and NASA, having as long-term goal an international Mars sample return mission.

The RSP (Rover and Surface Platform) mission of the ExoMars program of ESA will deliver a European ExoMars Rover and a Russian Surface Platform to the surface of Mars. The primary objective is to land the rover at a site with high potential for finding well-preserved organic material, particularly from the very early history of the planet.

ExoMars RSP (Rover and Surface Platform) Mission and System Concept

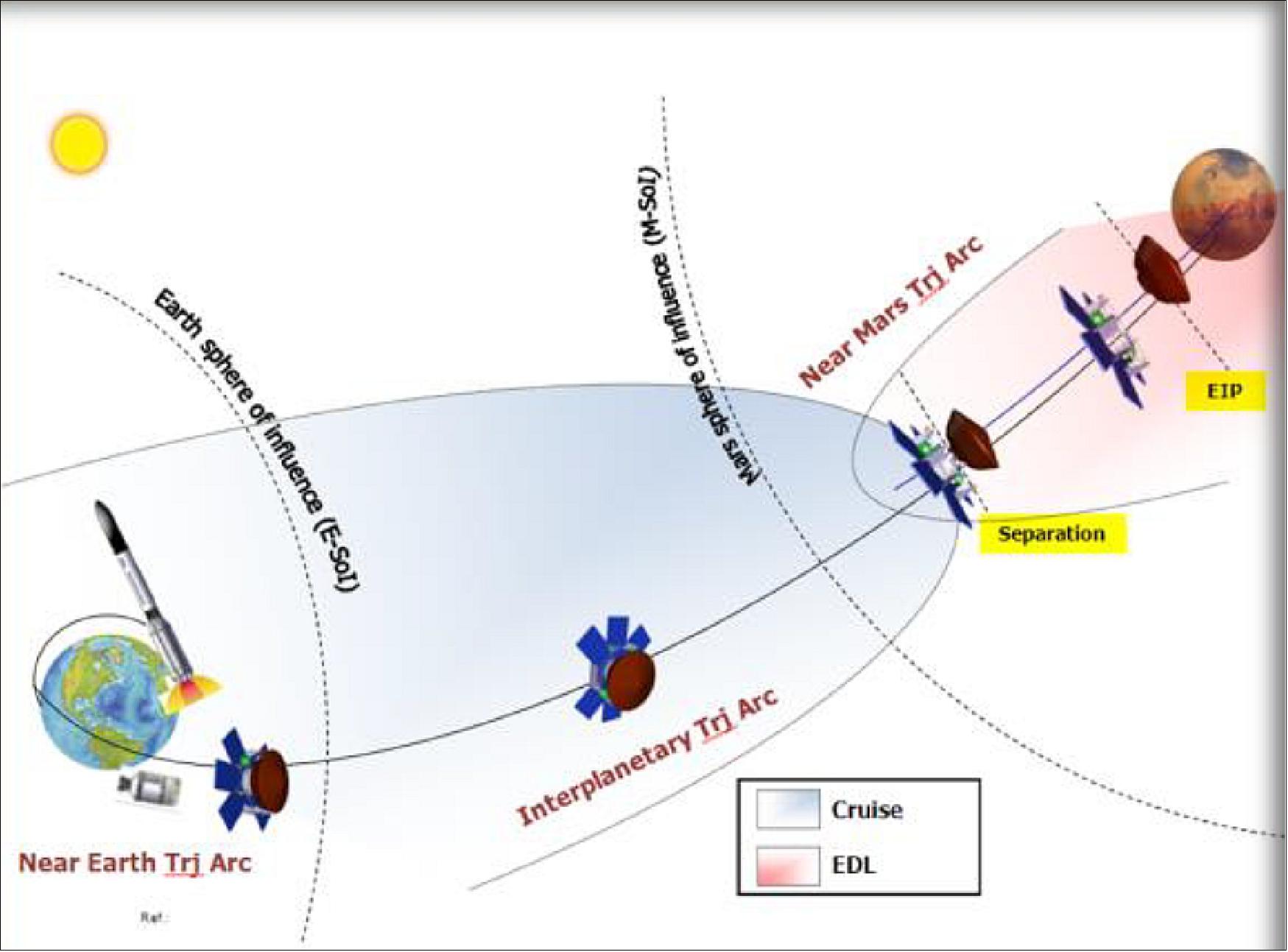

The ExoMars RSP mission is foreseen to be launched into a direct transfer to Mars in July 2020. The transfer is ballistic; there are no deterministic Deep Space Maneuvers (DSM), only stochastic navigation maneuvers, some of which have a deterministic component for planetary protection reasons (Ref. 1). 4) 5) 6) 7) 8)

In the current mission design, the launch period has a duration of 20 days. Out of these 20 days, with the six allocated Proton-M/Breeze-M launcher programs, it will be possible to have at least six days of launchability within the launch period arranged in groups of two: two days at the start, two in the middle and two at the end of the launch period. The days in between are gaps of non-launchability.

All dates in a given launch period lead to arrival on the same date. This simplifies operations planning and ground station booking, though it also removes one degree of freedom from the trajectory design.

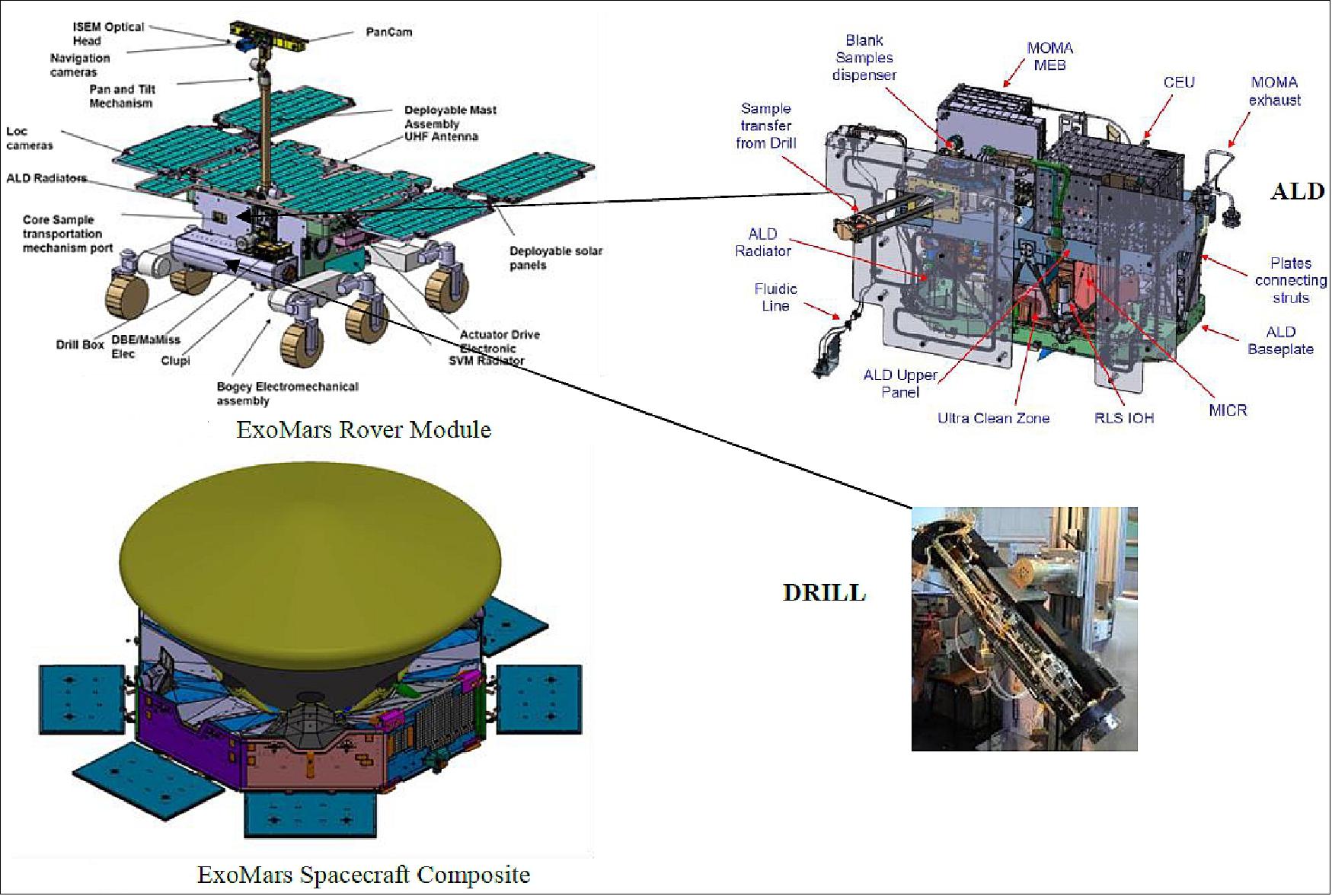

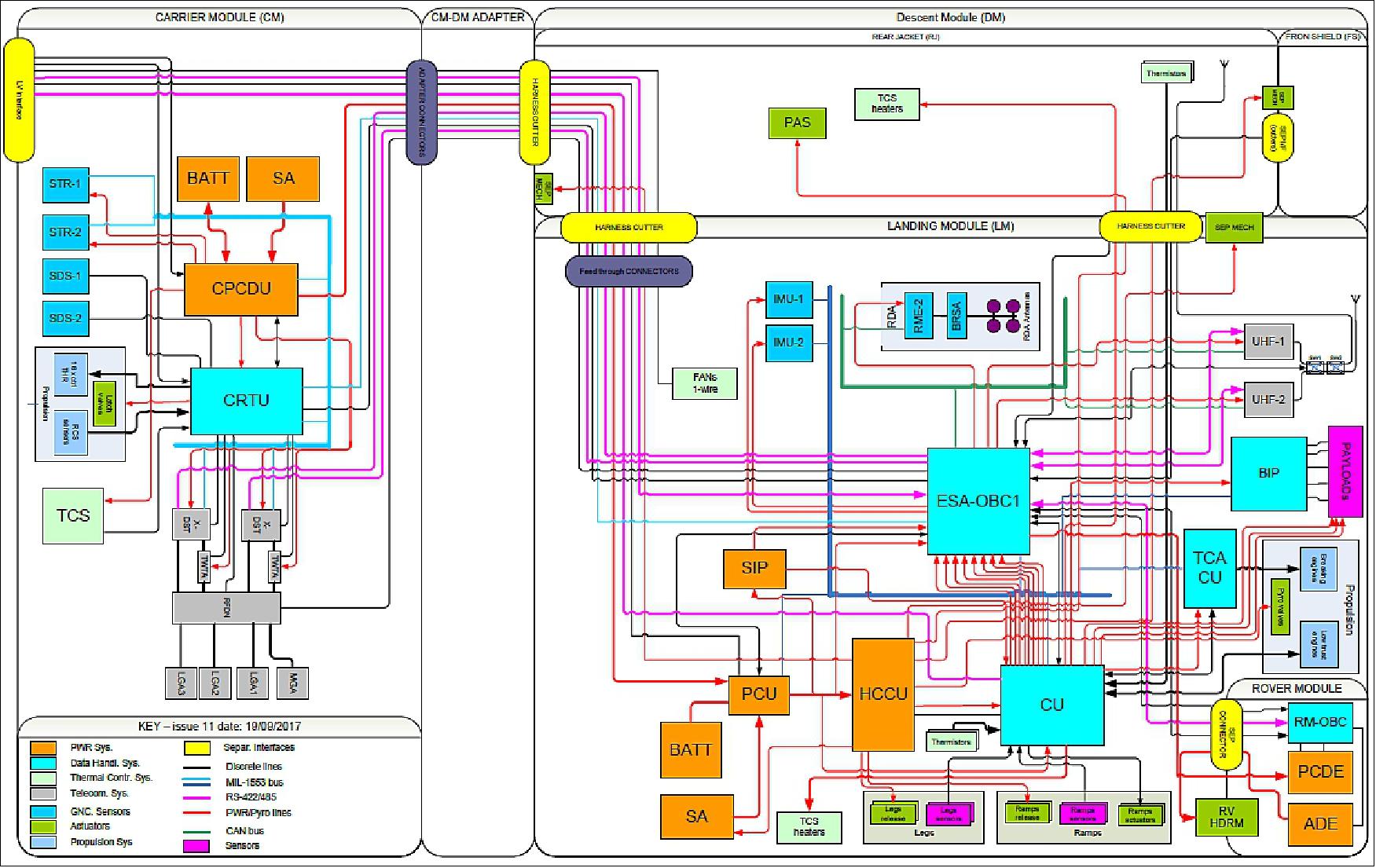

The 2.9 ton SCC ( SpaceCraft Composite), developed by Thales Alenia Space in Italy under ESA contract, is composed of a CM (Carrier Module) and a 2 ton DM (Descent Module) provided by Roscosmos of Russia, which carries the 350 kg RM (Rover Module), also provided by ESA.

Industrial consortium: On the 2020 mission, Thales Alenia Space in Italy, is in charge of the design, development and verification of the entire system, the development of the Carrier Module navigation and guidance system and perform EDL/GNC development, the Rover System, including the Analytical Laboratory Drawer (ALD) as well as supplying basic parts of the DM, including the Radar Altimeter. In addition, Thales Alenia Space in Italy implements a deep technical partnership with Lavochkin for the development of the Descent Module (DM). OHB is in charge to develop the CM as well as ALD SPDS Mechanism and delegated tasks, the Rover Vehicle itself is provided by Airbus Defence and Space in UK. Leonardo is developing the ExoMars 2020 drill, which will dig into the Mars subsoil to a depth of two meters and ALTEC (Aerospace Logistics Technology Engineering), a Thales Alenia Space in Italy (63.75%) and ASI (36.25%) company – will also be responsible for the design, development and maintenance of the ROCC (Rover Operation Control Center) and for controlling the Rover on the Martian surface (Ref. 58).

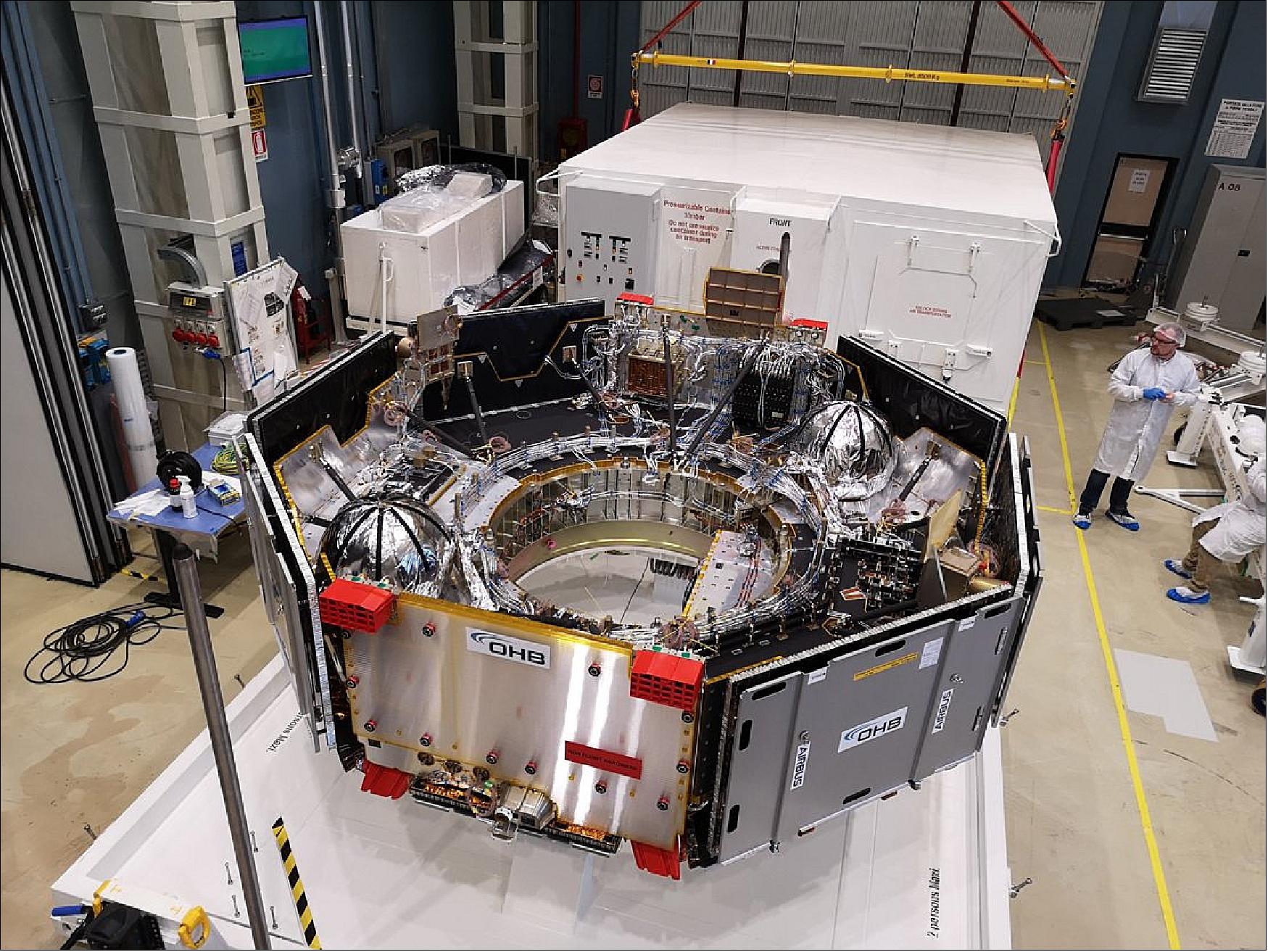

The CM (Carrier Module), developed by OHB (Bremen, Germany), implements all the tasks needed to carry the whole system close to Mars atmospheric borders. It executes all the necessary maneuvers in interplanetary transfer and targets the trajectory such that the DM will enter at the required entry flight path angle and that the lander will touch down at the required location. Separation of the CM from the DM is currently foreseen to occur at EIP-30 minutes. The CM is not foreseen to operate after separation form the DM (Descent Module).

The CM and DM modules are mated by means of a separation mechanism bolted on both sides on 8 I/F points (pyrolocks on DM Rear Jacket side). Cable disconnection at separation is implemented by cutters.

The DM (Descent Module), developed by Lavochkin (Ru) with the contribution of key European Hardware and Software system contributions (see below), is a blunt-shape reentry capsule made of four separate main parts, FS (Front Shield), RJ (Rear Jacket), LP (Landing Platform) and PAS (PArachute System), performs the Entry, Descent and Landing on the Martian surface of a Landing Platform.

In particular the European Hard- and Software contributions consists of:

• The On-Board Computer, developed by Crisa (E), which manages the whole ExoMars 2020 mission during Cruise, EDL and Mars Surface Operation phases running the whole Mission Software,, developed by TAS (I).

• The IMU (Inertial Measurement Unit), developed by Airbus Defence and Space (ADS-F), which supports GNC during both Cruise and EDL phases

• The Radar Altimeter, developed by TAS (I), which is used to control the landing phase

• The UHF Transponder and Landing Platform Antenna, developed, respectively, by QinetiQ (UK) and Tryo (E), used for the proximity communications with the TGO

• The PArachute System, developed by TAS (F).

The DM accommodates the RM and provides for its egress to the Martian surface.

The LP (Landing Platform), following the departure of the Rover, becomes SP (Surface Platform) for a long-lived stationary science instrument suite to study the Martian environment at the landing site. The 45 kg instrument suite with a planned lifetime of 2 Earth years is foreseen to consist of twelve instruments: In particular:

- TSPP (4 Cameras)

- MTK (Meteorology Package)

- RAT-M (Radiometer)

- MAIGRET (magnetometer)

- SAM (Seismometer)

- LaRa (Radioscience Mars Geodesy)

- PK (Dust Studies)

- M-DLS (Atmospheric Laser Spectrometer)

- FAST (Trace Gas Fourier Spectrometer)

- MGAK (Gas Analytical Package)

- Adron-EM (Neutron Spectrometer)

- HABIT (Humidity And Radiation Sensor)

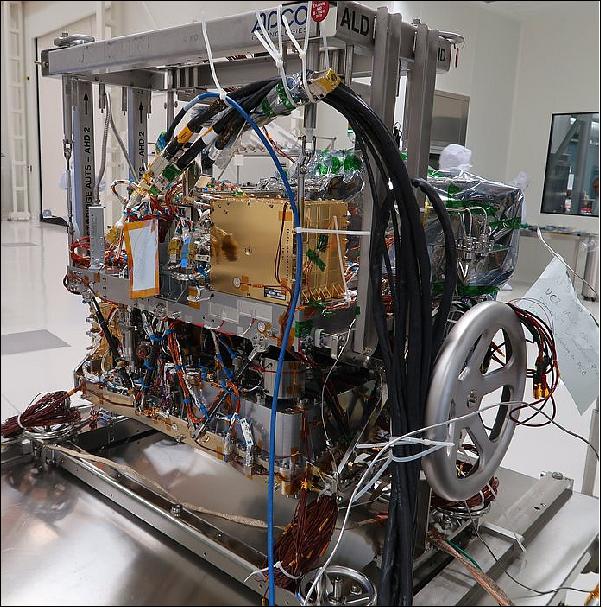

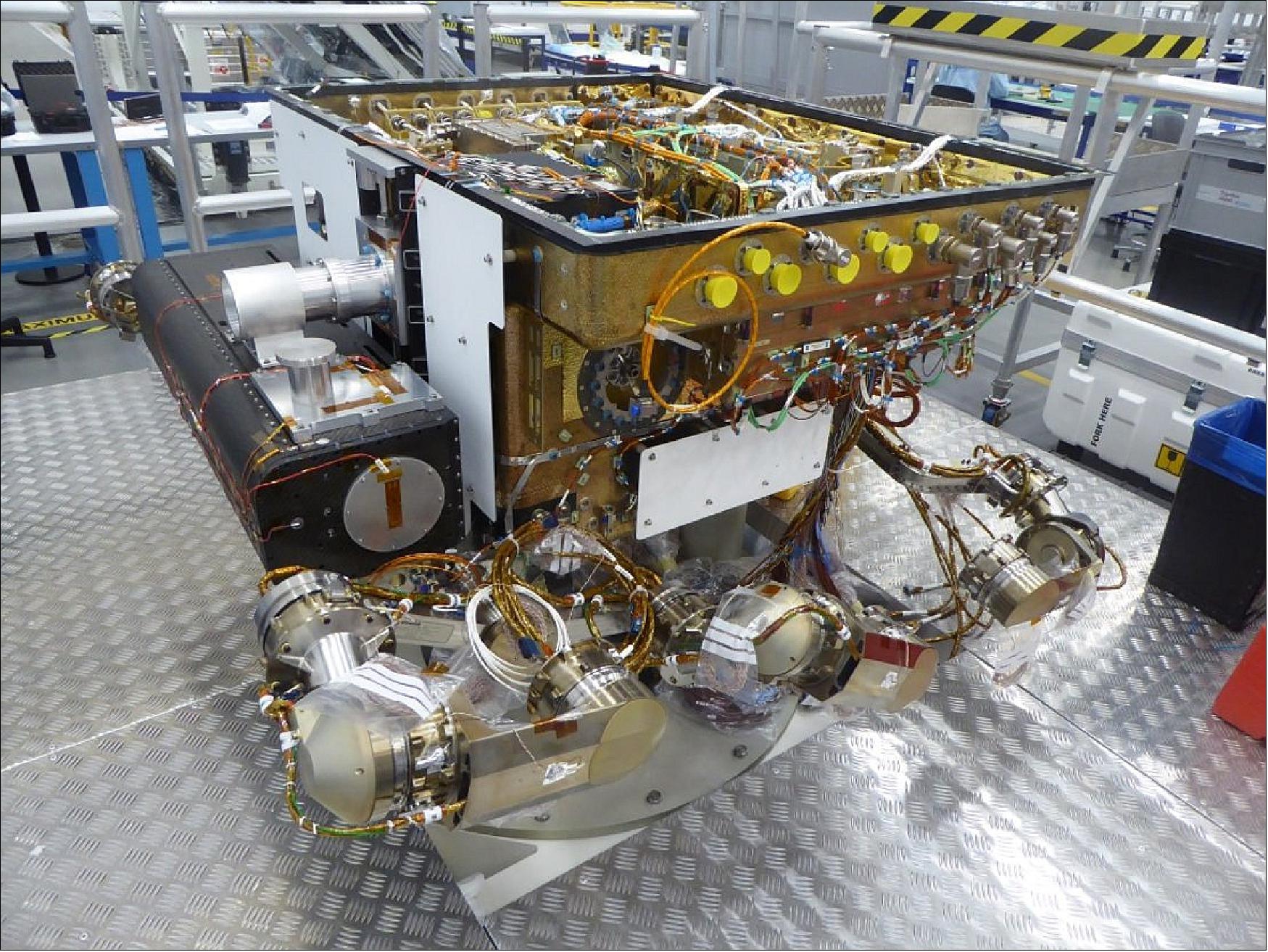

The RM (Rover Module), developed under the responsibility of TAS (I), consists of a RV (Rover Vehicle) which carries an ALD (Analytical Laboratory and Drill) for subsurface sampling (down to 2 m).

The RV is made by Airbus Defence and Space (ADS-UK), the ALD is developed by TAS (I) with OHB (D) providing the sample processing and handling mechanisms and the Drill is developed by Leonardo (I) . The Rover Module contains European, Russian and NASA scientific payloads. The Rover is designed to deploy and egress from the DM Landing Platform, and to perform science exploration on the Mars surface with a suite of dedicated instruments.

RM Scientific package consists of the Pasteur Payload (PPL) composed of:

• 6 Survey Payloads

- Panoramic Cameras (WACs + HRC) PanCam

- Ground Penetrating Radar for Water Ice Subsurface Deposit Observation on Mars - WISDOM

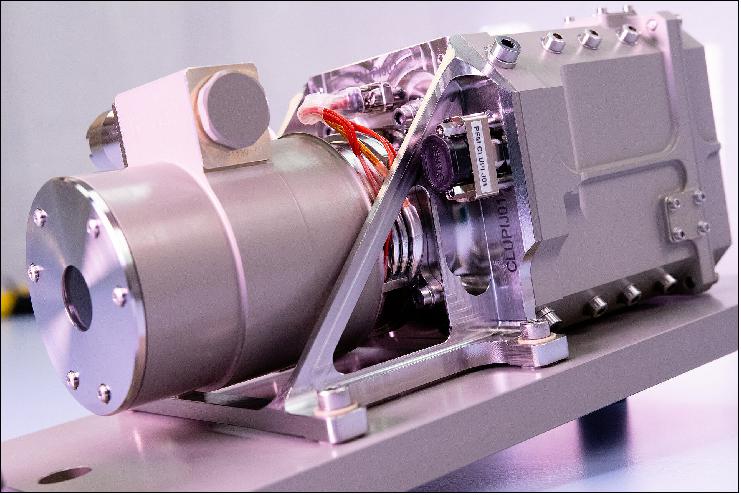

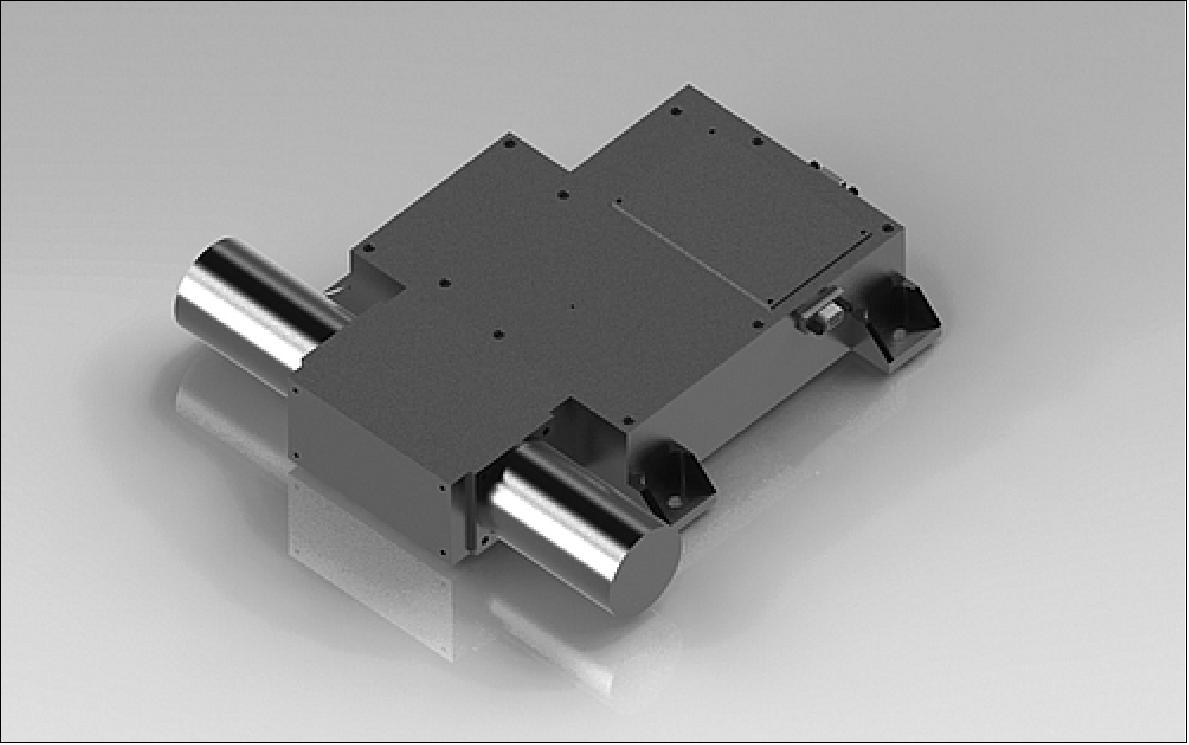

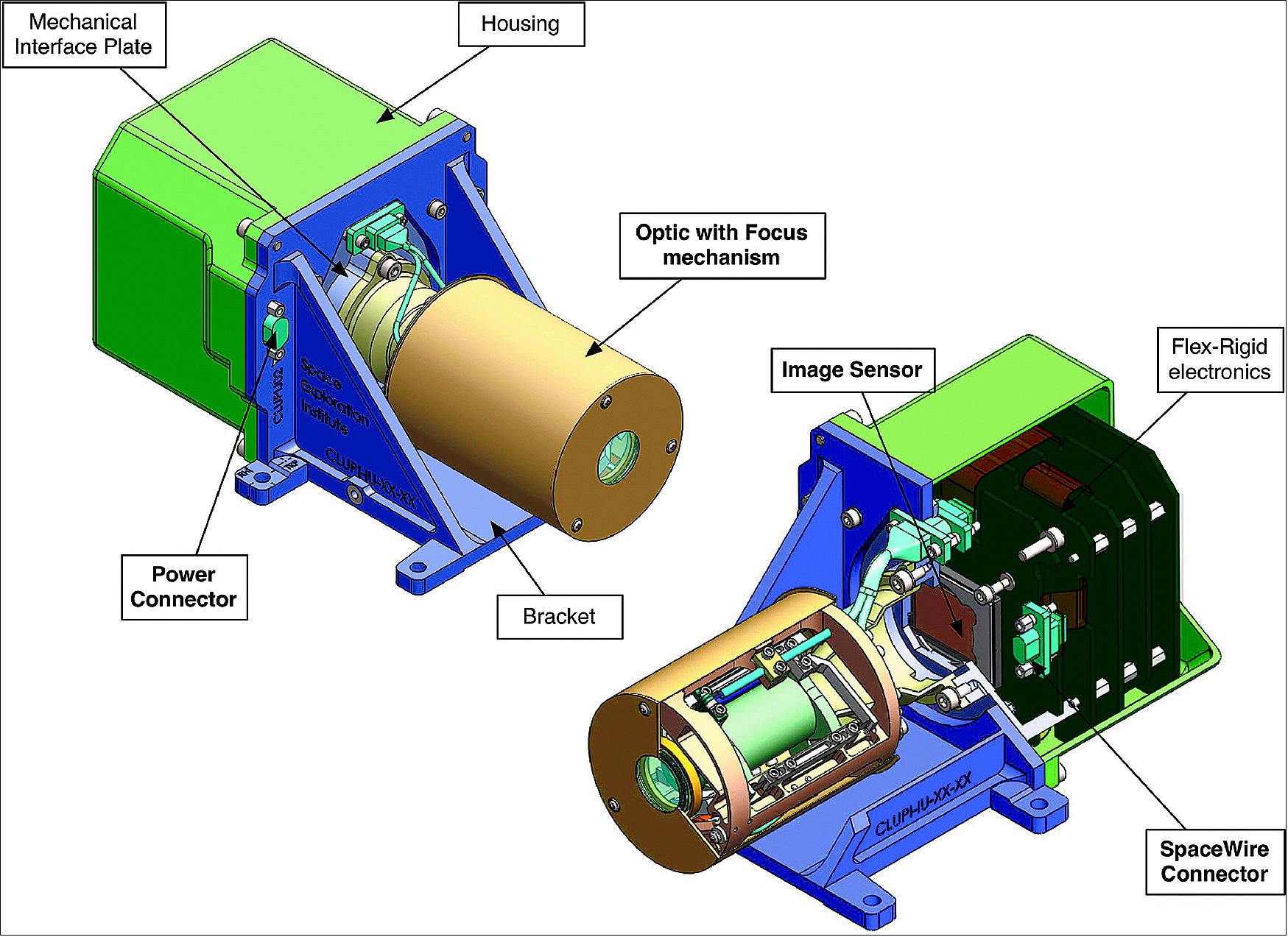

- Close-Up Imager - CLUPI

- Mars Multispectral Imager for Subsurface Studies - Ma_Miss (in Drill)

- Neutron Detector – ADRON-RM (Roscomos - IKI)

- Infrared Spectrometer for ExoMars - ISEM (Roscomos - IKI)

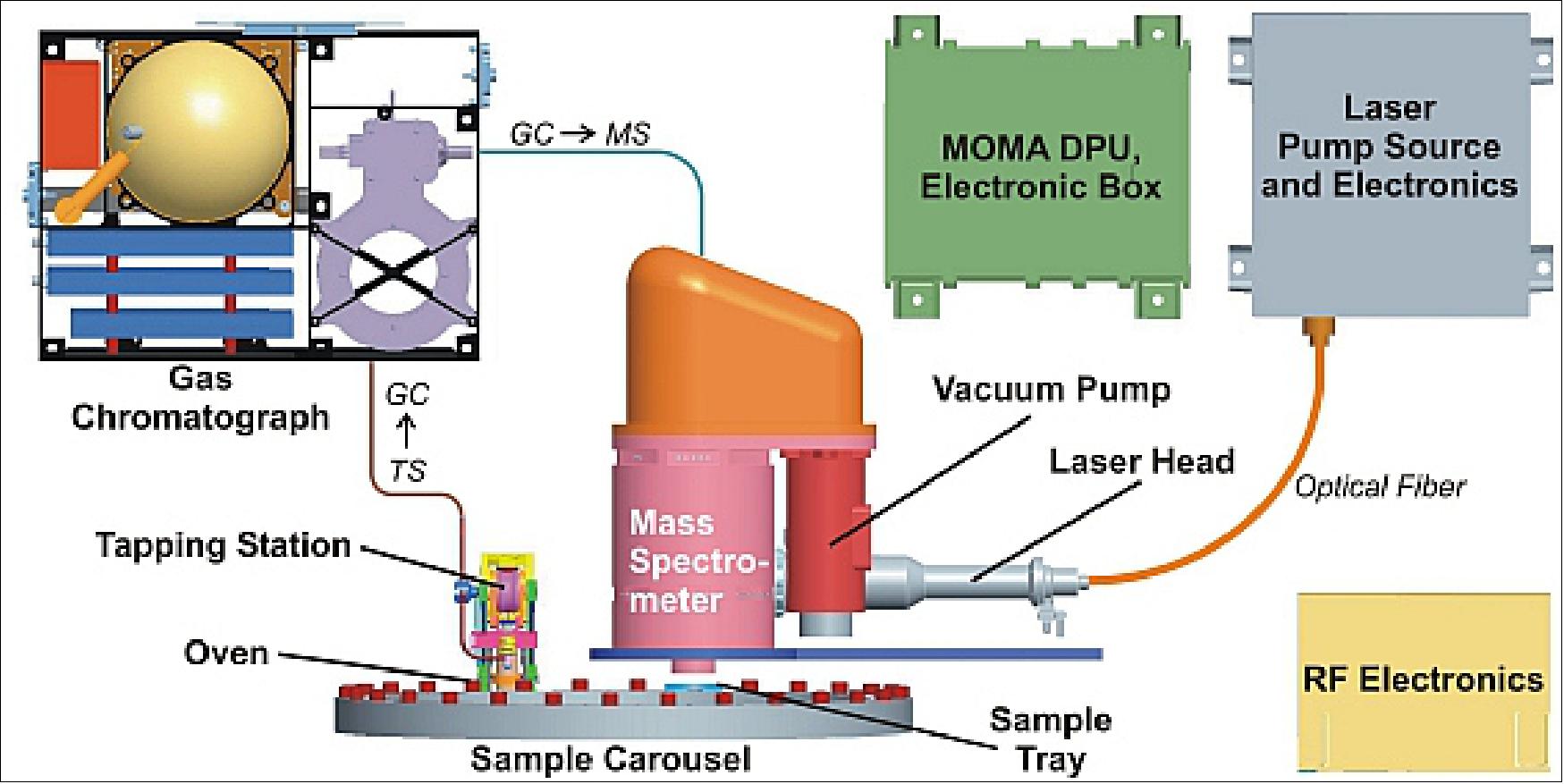

• 3 Analytical Payloads (part of ALD)

- Infrared Microscope (MicrOmega)

- Raman Laser Spectrometer (RLS)

- Mars Organic Molecule Analyzer - (MOMA)

Note: The ALD is an integrated laboratory able to collect and prepare Martian terrain specimen from the Drill, handle and process them to the on board scientific instruments for in situ analysis, in a ultra-clean environment.

ExoMars RSP Mission Management

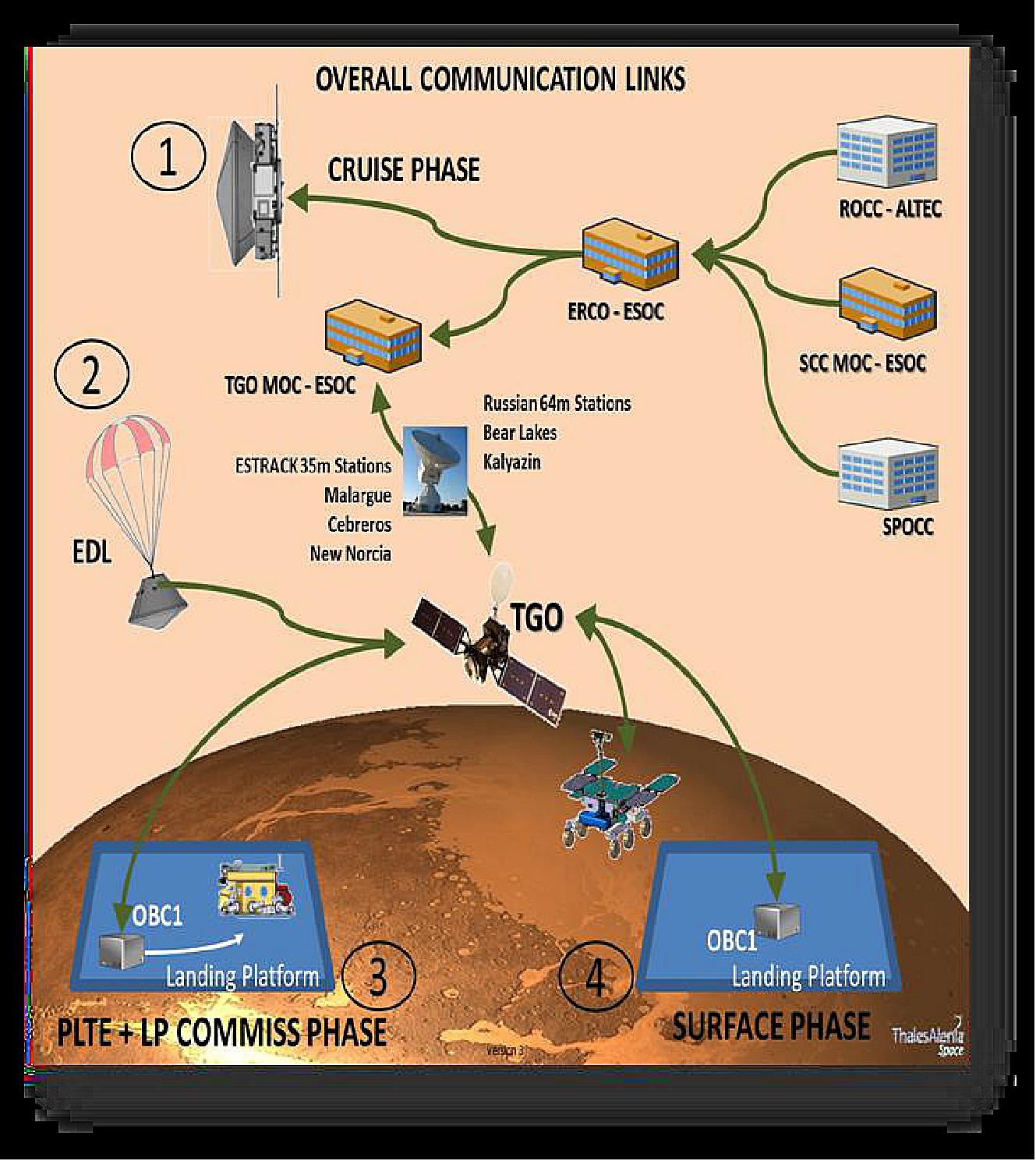

The 2020 mission operations, planning and execution will be performed by the MOC (Mission Operation Center) located at ESOC in Darmstadt with the support of:

• the SCC MOC

• the Rover Operations Control Center (ROCC)

• the Surface Platform Payload Operations Control Center (SPOCC)

• the TGO MOC, starting only from the EDL phase.

In particular ESOC/MOC will be responsible of controlling the SCC (and DM/LP) since Launcher separation up the Rover egress on the Mars surface. ESOC/MOC will be also responsible through ERCO (ESA Relay Coordination Office) in leading the ESA Data Relay Orbiter operations acting as data communication hub also to/from ROCC and SPOCC, starting from Launch until the egress of the RM after the LP landing on the Martian surface. Note: this very delicate last phase of the mission is named Post Landing to Egress (PLTE). 9)

After the RM egress, the ExoMars Rover mission will be independent and developed under the full responsibility of the ROCC while the Landing Platform Mission will be under the responsibility of the SPOCC (both via ERCO).

The X-band communications will use:

• The ESA Ground Station & Communications Subnet (ESTRACK)

• The NASA Ground Stations & Communication Subnet (DSN), to be considered for “critical phases“ like Safe Mode(s) or Flight Software upload or for “extreme contingencies” like the loss of SCC attitude

• The Russian Ground Stations & Communication Subnet (RNS).

During the LP (Landing Platform) mission the communication are performed via UHF band between On Board Computer (OBC1) and TGO (or NASA available Orbiters) during scheduled communication windows on visibility passes.

The Science Data Archive will make use of:

• The Pasteur payload Science Data Archiving and Dissemination located at ESAC, Spain

• The Science Data Archiving centers (NASA PDS and ESA PSA)

• Russian Science Ground Segment (NNK).

ExoMars RSP System Architecture

Hereafter, pictorial views of the main components of the ExoMars 2020 spacecraft together with the avionics block diagram are shown.

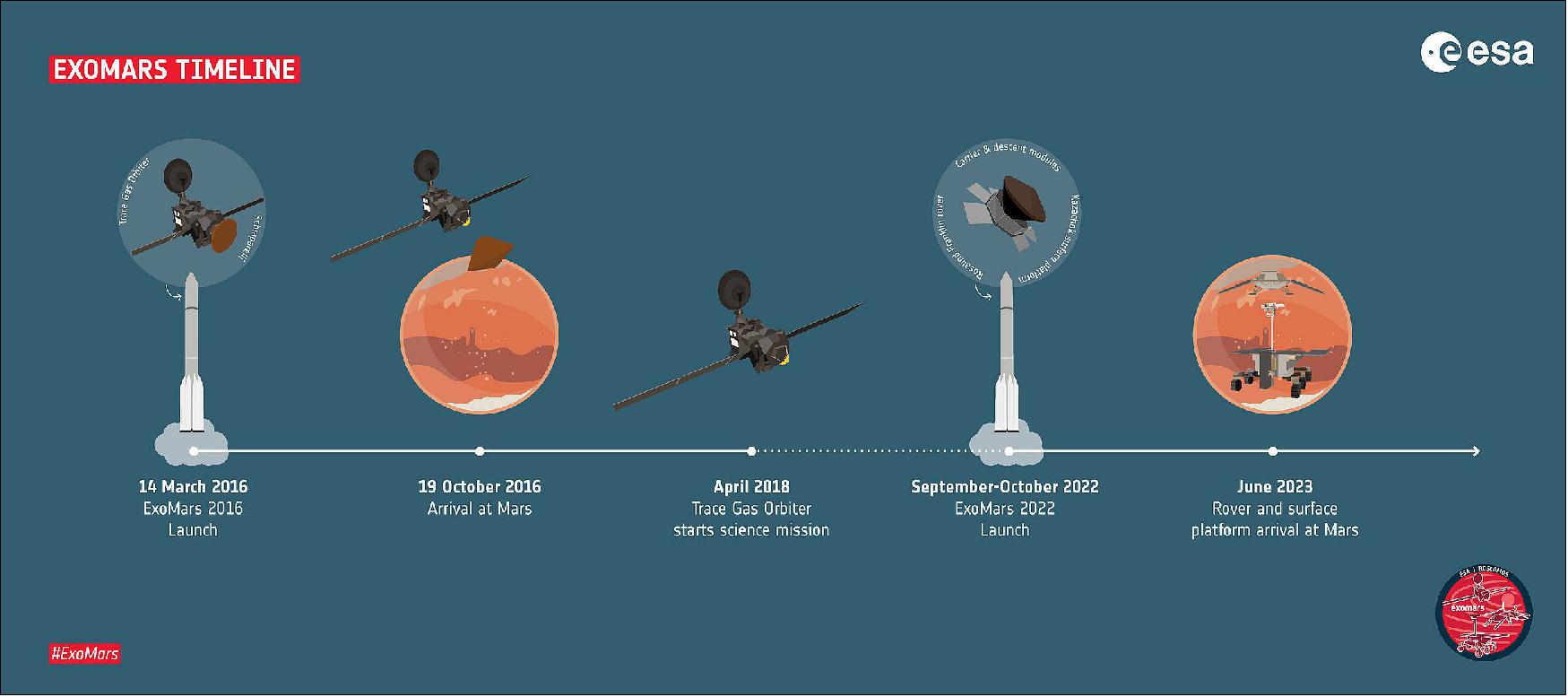

Note: As of March 2020, the European Space Agency (ESA) and the Roscosmos Space Corporation have decided to postpone the launch of the second ExoMars mission to study the Red Planet to 2022 (Ref. 31). The mission is now called ExoMars 2022.

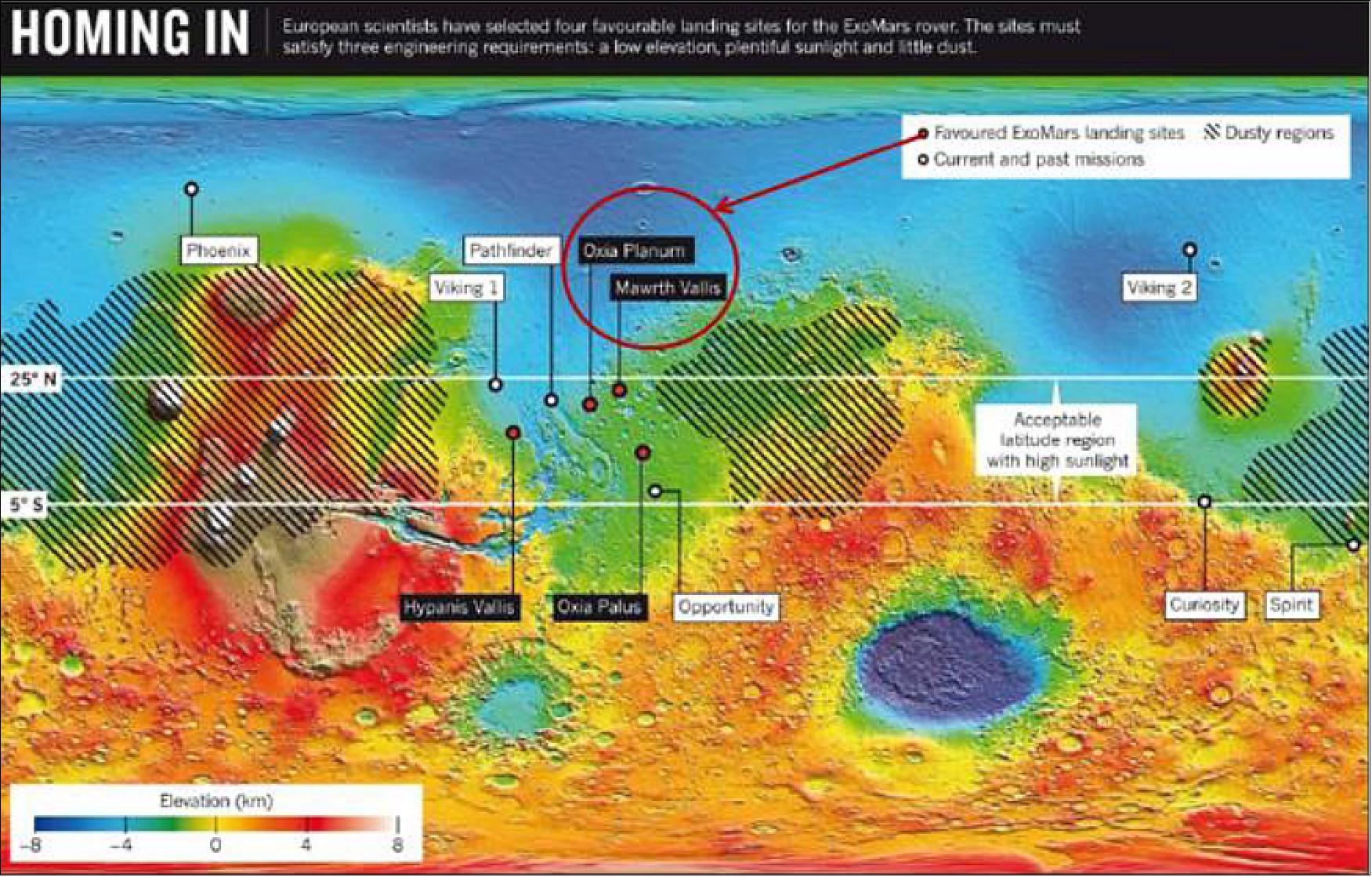

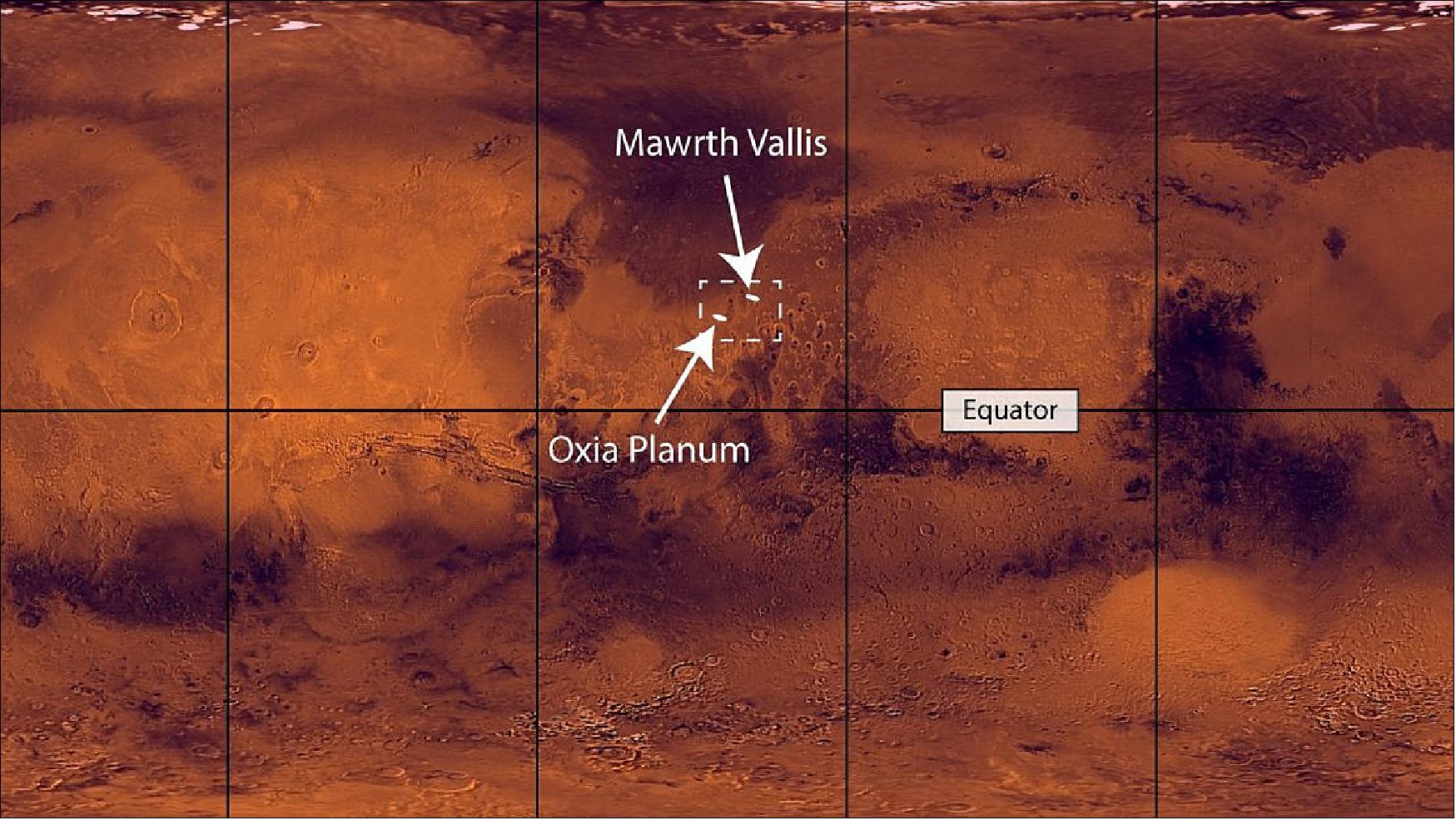

Launch: In 2020, the new launch date of the ExoMars 2022 mission was scheduled in the 20 September-1 October 2022 launch window on a Proton rocket with a Breeze-M upper stage of Roscosmos from the Baikonur Cosmodrome (Kazakhstan) and arrive in the Oxia Planum region of Mars on 10 June 2023. 10) However, due to disruption with virtually all Soyuz launch agreements internationally, the Proton rocket launch for the ExoMars mission in September 2022 will not proceed (Ref. 13).

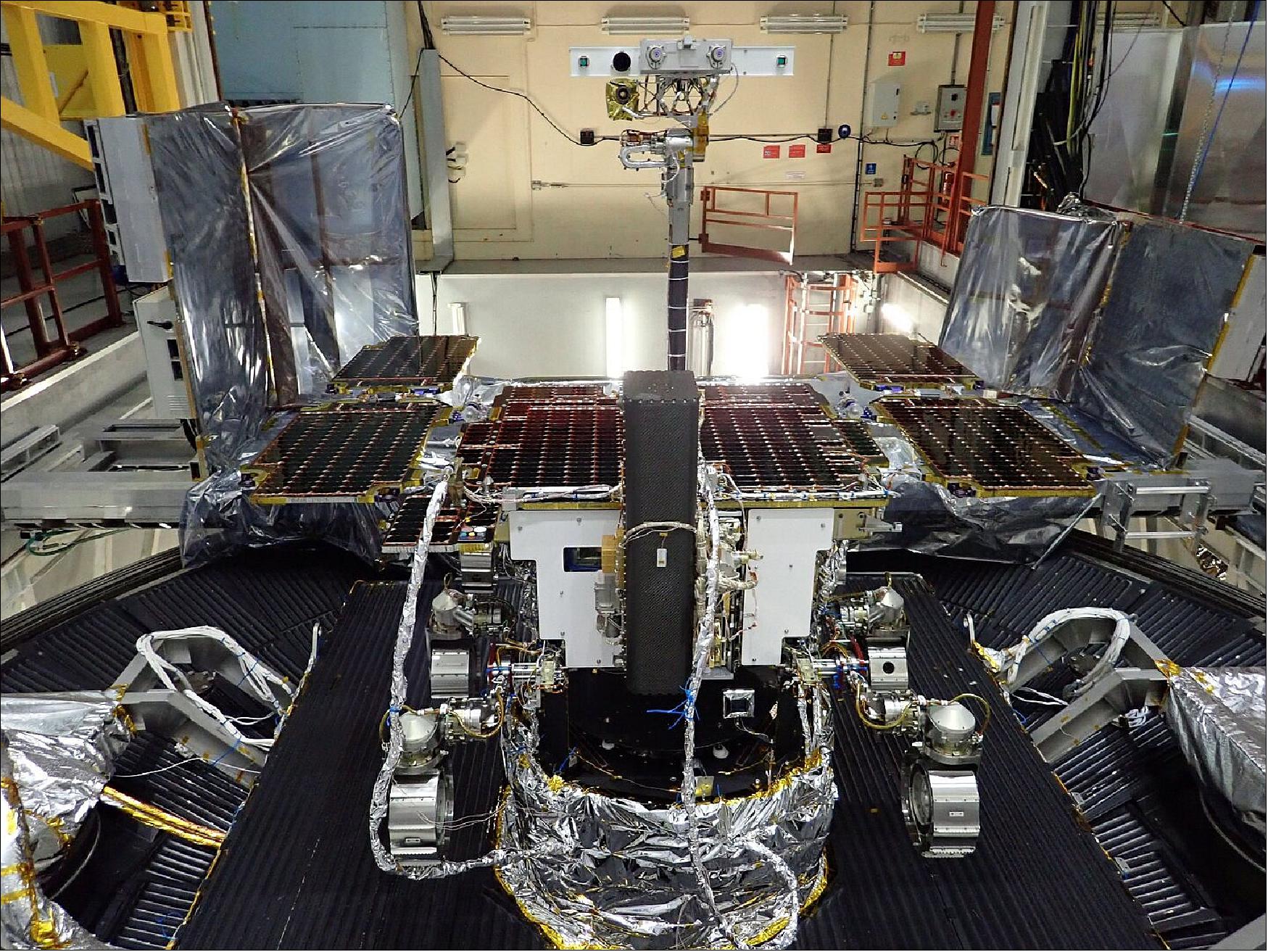

Rover ready – next steps for ExoMars

March 28, 2022: ESA’s ExoMars rover is confirmed technically ready for launch, and a fast-track study is under way to determine options for bringing the mission to Mars. 11)

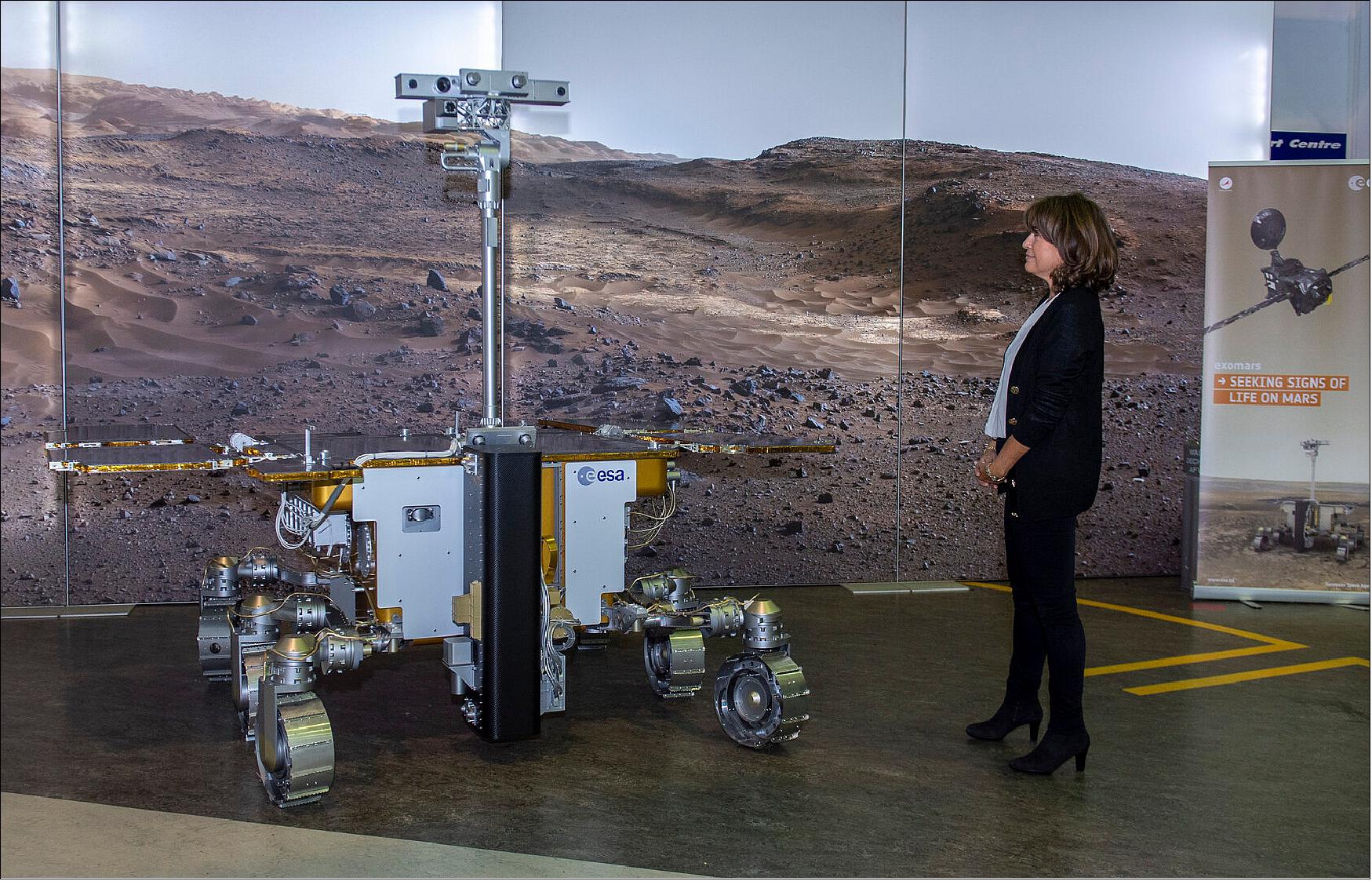

The ESA-led Rosalind Franklin rover has a unique potential to search for evidence of past life on Mars thanks to its drill and laboratory. It will be the first rover to drill 2 m below the surface, and the first to use novel driving techniques, including wheel-walking, to overcome obstacles.

Although the 2022 launch window for the mission is no longer possible following the suspension of cooperation with Roscosmos, the mission’s System Qualification and Flight Acceptance Review took place as planned in March. The Review Board confirmed that the spacecraft would have been ready for the timely shipment to the launch site and the programme had a sufficient time margin for the original launch opportunity opening on 20 September 2022.

Due to the suspension of the 2022 launch, the ExoMars elements are now being prepared for storage at a Thales Alenia Space site in Italy awaiting further instruction.

The Review Board members specifically expressed their appreciation and thanks to the review team for the exhaustive work performed over the past months.

Based on the decision by ESA Member States at its March Council meeting, a fast-track industrial study will now start to better define the available options for a way forward to implement the ExoMars rover mission in a future launch.

The teams will be looking for the earliest possible launch depending on how quickly technologies can be developed to support a European-led mission, or in collaboration with other international partners, and the availability of compatible launchers and launch site.

“I hope that our Member States will decide that this is not the end of ExoMars, but rather a rebirth of the mission, perhaps serving as a trigger to develop more European autonomy,” says David Parker, Director of Human and Robotic Exploration at ESA.

“We count on brilliant teams and expertise across Europe and with international partners to reshape and rebuild the mission. The team is dedicated and focused on setting out the next steps to ensure we bring this incredible rover to Mars to complete the job it was designed for.”

Meanwhile, the ExoMars Trace Gas Orbiter (TGO) continues to relay the majority of data from Mars, from NASA’s Curiosity and Perseverance rovers as well as its Insight lander. TGO has considerable fuel onboard meaning it could also support data relay from the ExoMars rover in the future as well the Mars Sample Return campaign.

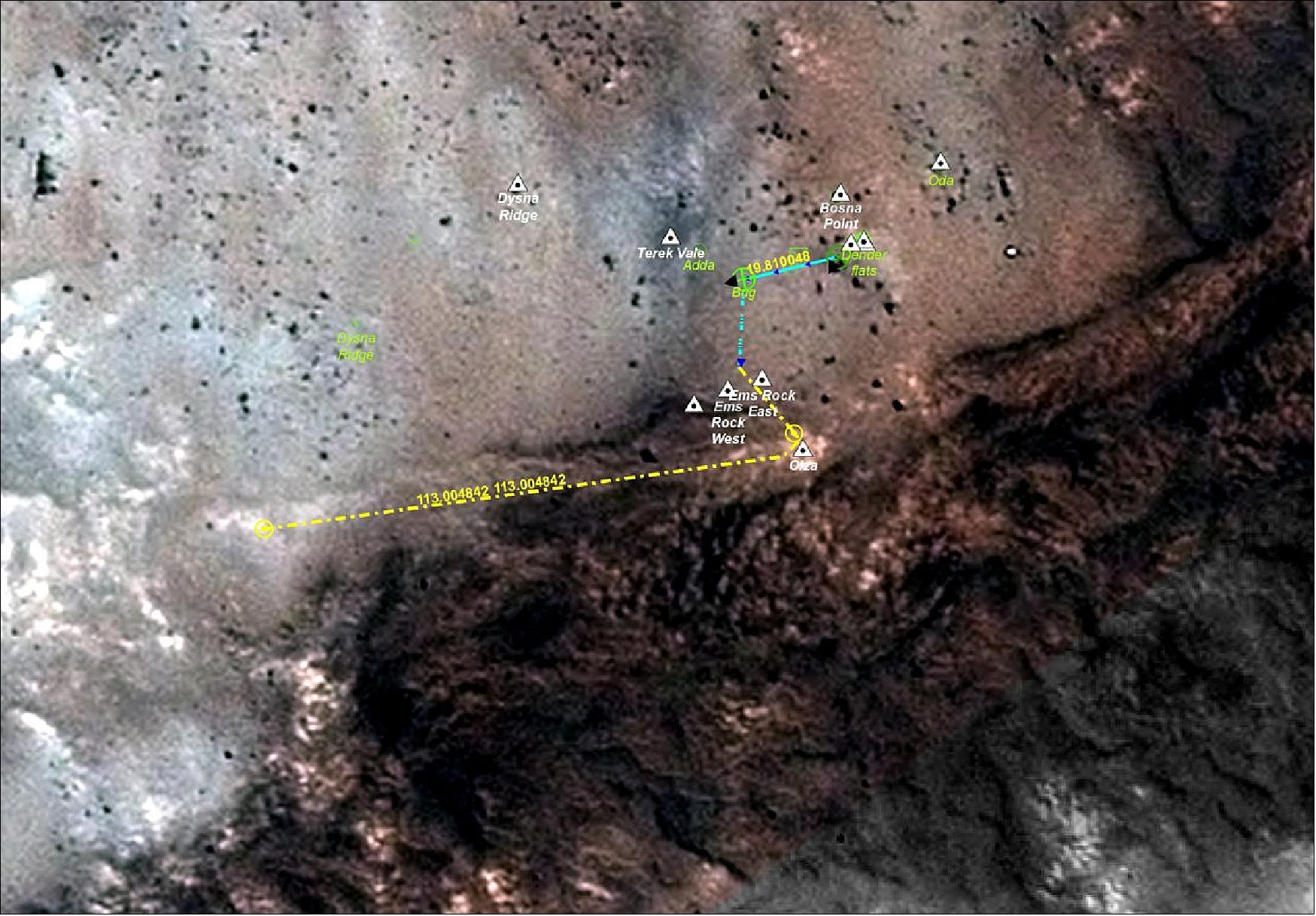

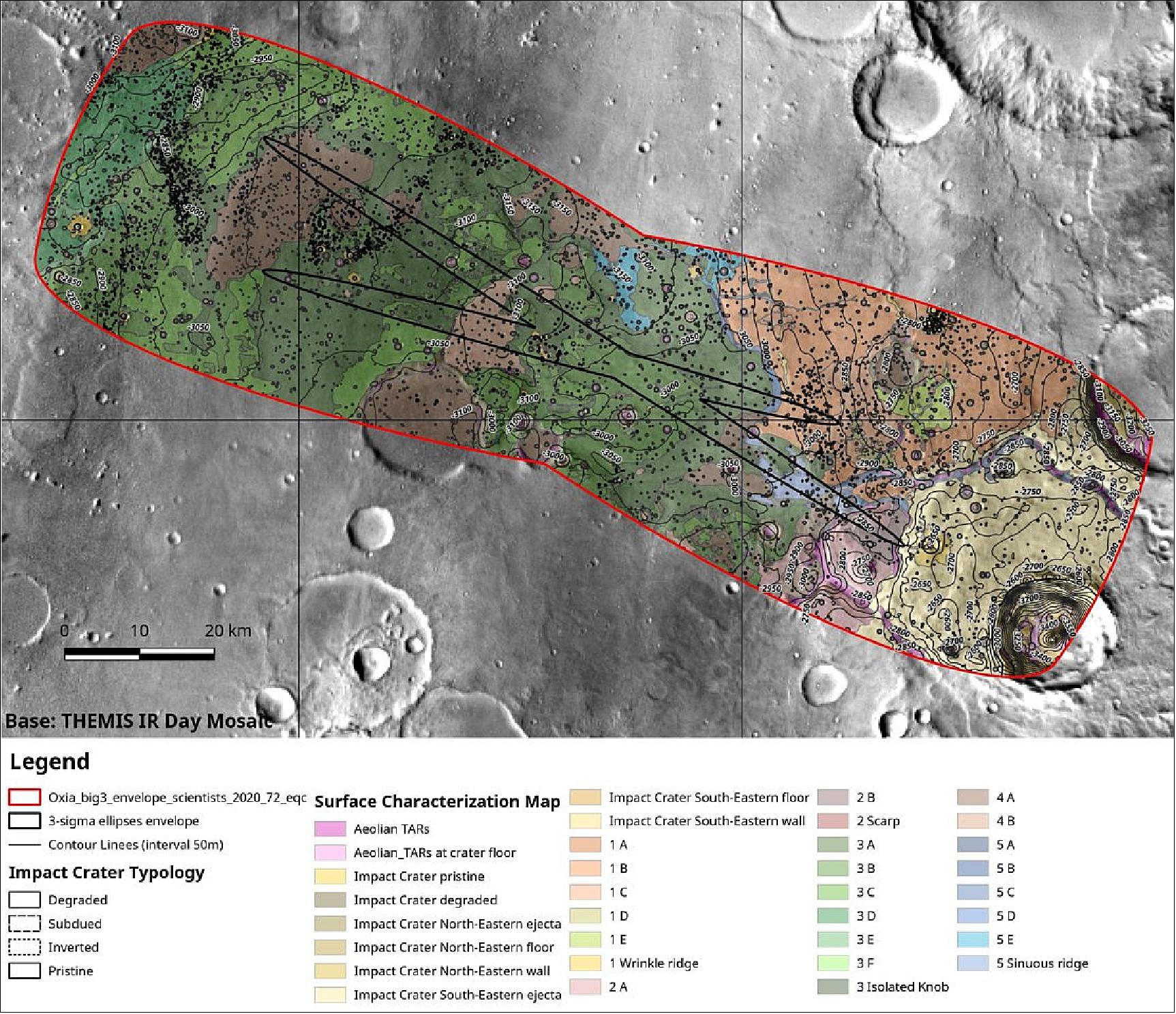

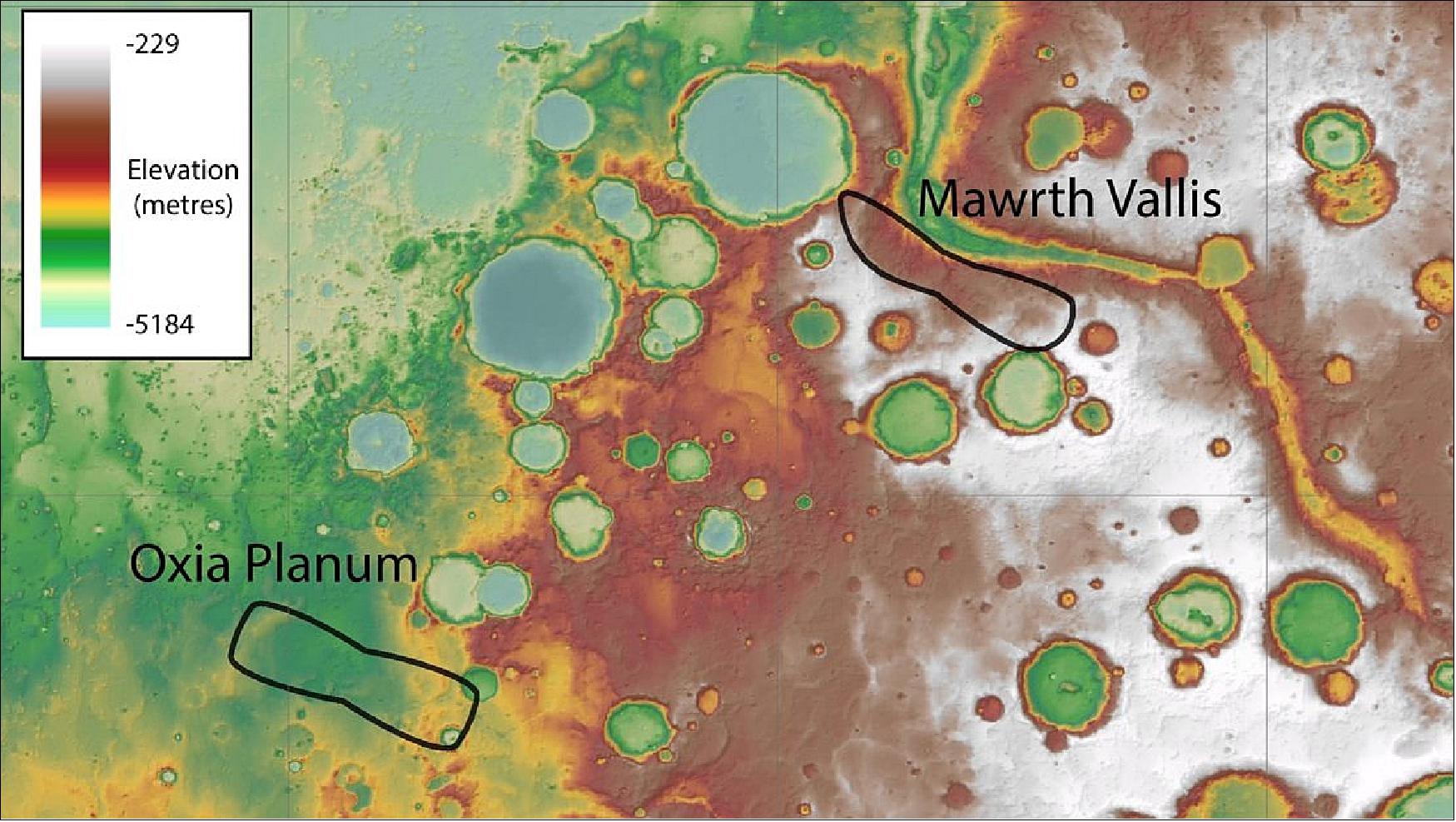

The ExoMars 2022 landing site is Oxia Planum, located in the northern hemisphere of Mars.

Development status of ExoMars 2022 - RSP (Rover and Surface Platform) Mission

Space Transportation

- Following the decision by Roscosmos to withdraw their personnel from Europe’s Spaceport in French Guiana, all missions scheduled for launch by Soyuz have been put on hold. These concern essentially four institutional missions for which ESA is the launch service procurement entity (Galileo M10, Galileo M11, Euclid and EarthCARE) and one additional institutional launch.

- Consequently, the ESA Director General has initiated an assessment on potential alternative launch services for these missions, which will include a review of the Ariane 6 first exploitation flights. A robust launch manifest for ESA missions’ launch needs, including for spacecraft originally planned for launch by Soyuz from Kourou, will be submitted to Member States.

The International Space Station

- The International Space Station Programme continues to operate nominally. The main goal is to continue safe operations of the ISS, including maintaining the safety of the crew.

Way forward

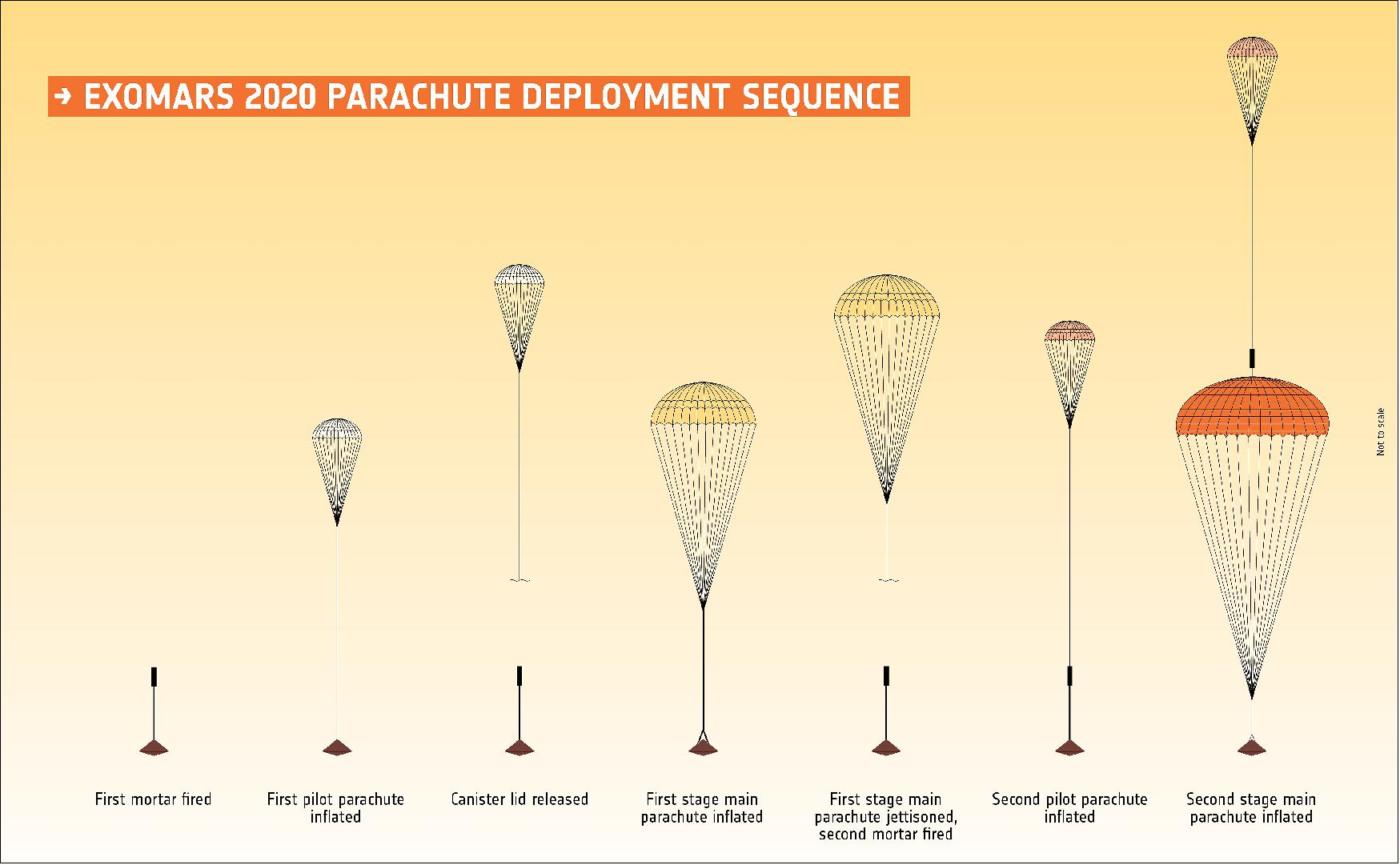

• December 14, 2021: The largest parachute set to fly on Mars has completed its first successful high-altitude drop test, a critical milestone for ensuring the ExoMars mission is on track for launch. Both the first and second stage parachutes have now successfully flown this year. 14)

- A pair of high-altitude drop tests took place in Oregon on 21 November and 3 December as part of the ongoing parachute testing to ensure the safe delivery of the ExoMars Rosalind Franklin rover and Kazachok lander to the surface of Mars in June 2023. The 35 m wide subsonic parachute – the largest ever to fly on Mars – was the focus of the latest campaign. One parachute was manufactured by European company Arescosmo, with the back-up provided by US-based Airborne Systems

- “Both parachutes deployed and flew beautifully,” says Thierry Blancquaert, ESA Exomars programme team leader. “We maximized the lessons learnt from all previous tests and with this double success following the impressive first stage parachute deployment earlier this year, we’re really on the road to launch. We have demonstrated we have two parachutes to fly to Mars.”

- The team will continue to test to verify the robustness of the final selection of parachutes, with more high altitude drop test opportunities possible in 2022 for both the first and second stage parachute. It is expected to fly the first stage parachute from Airborne Systems, and the second stage parachute by Arescosmo to Mars, pending the outcome of the March 2022 test campaign.

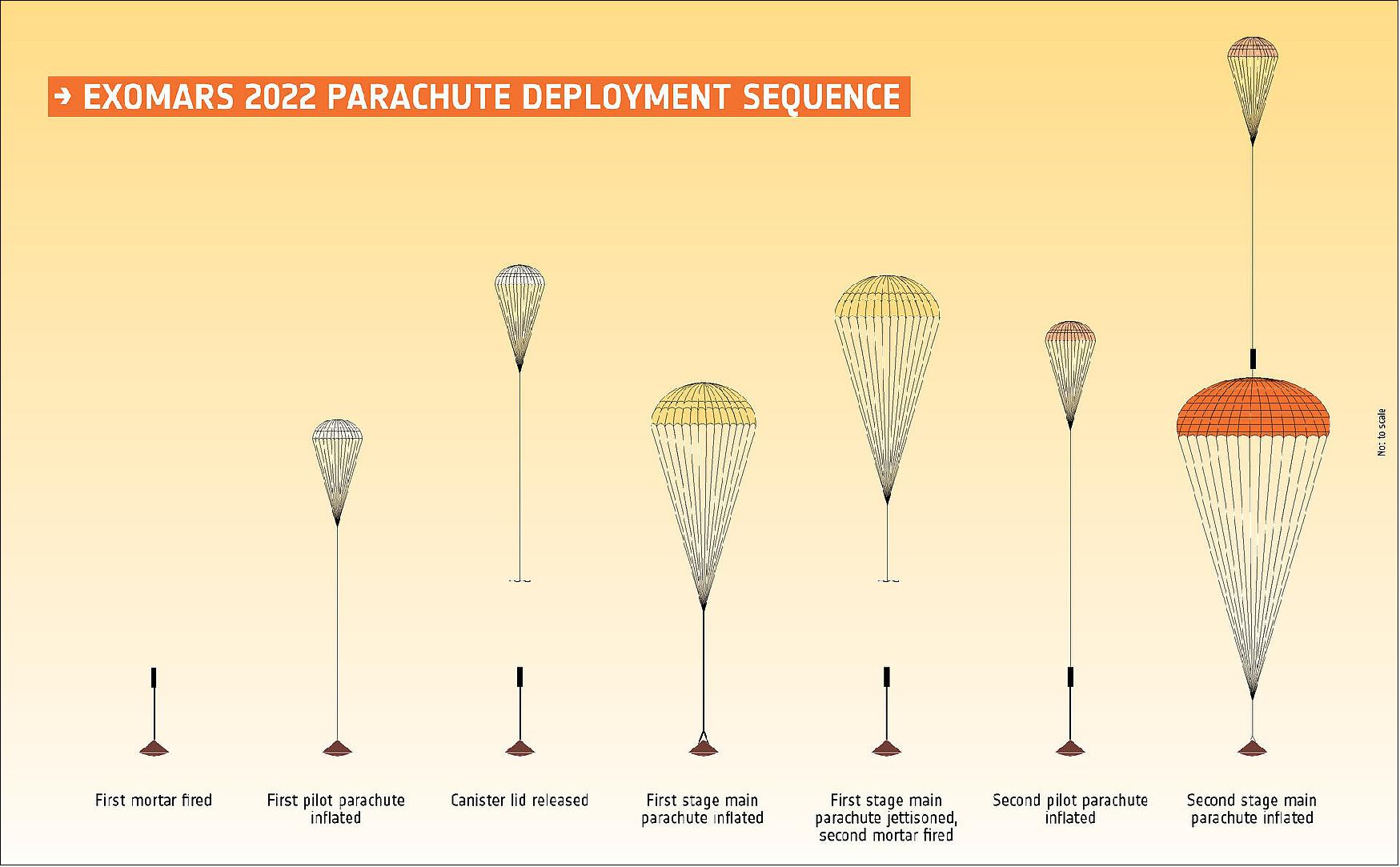

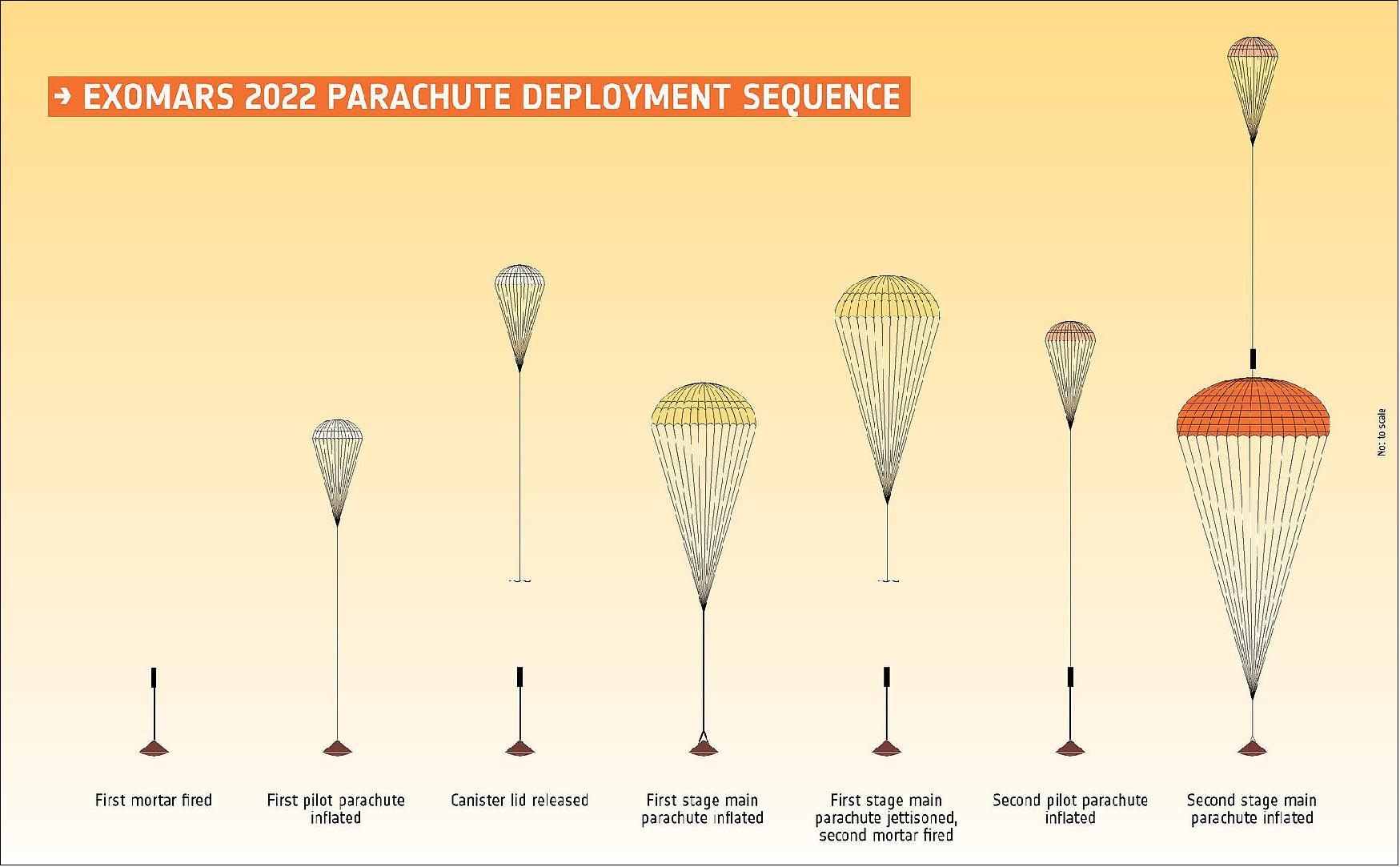

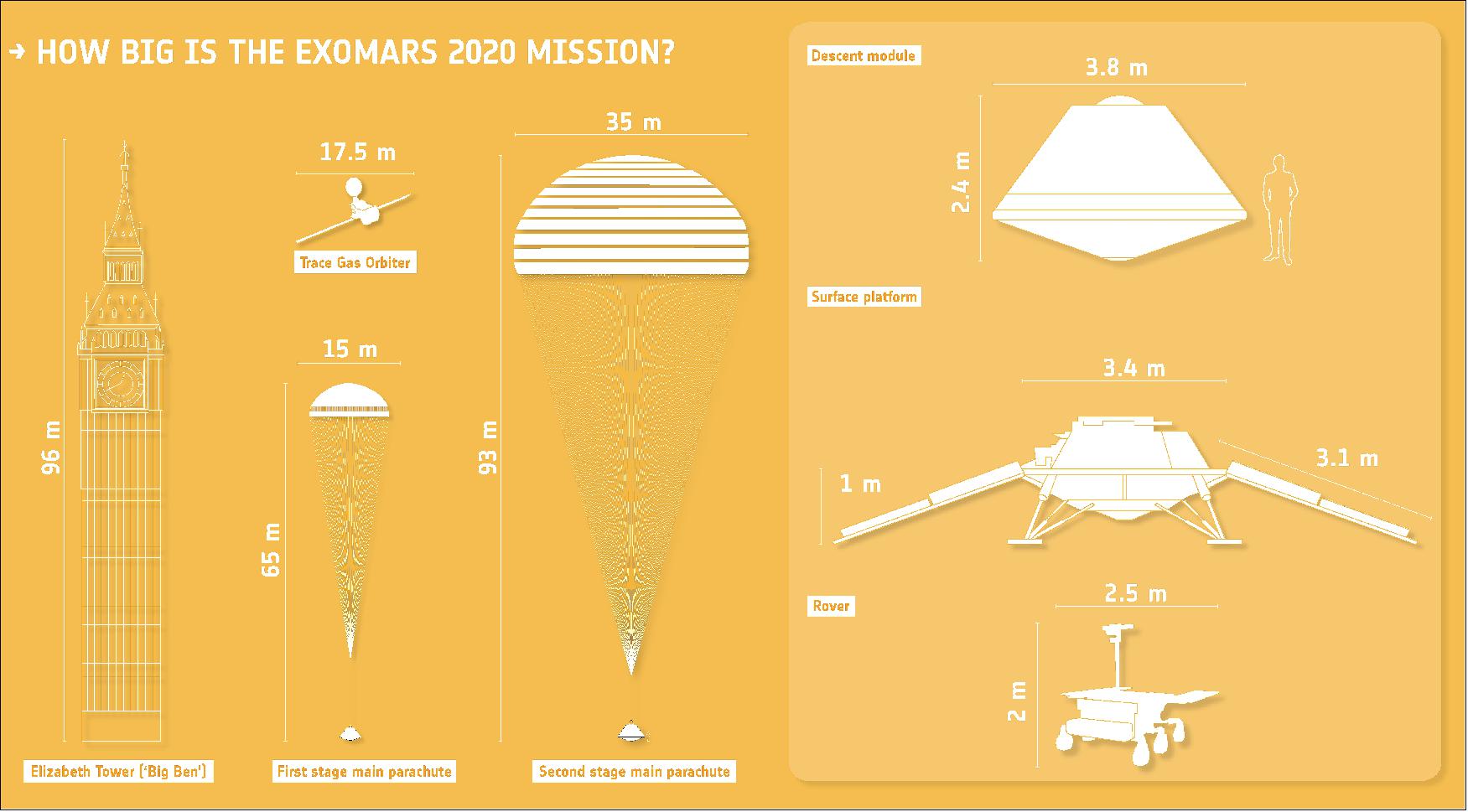

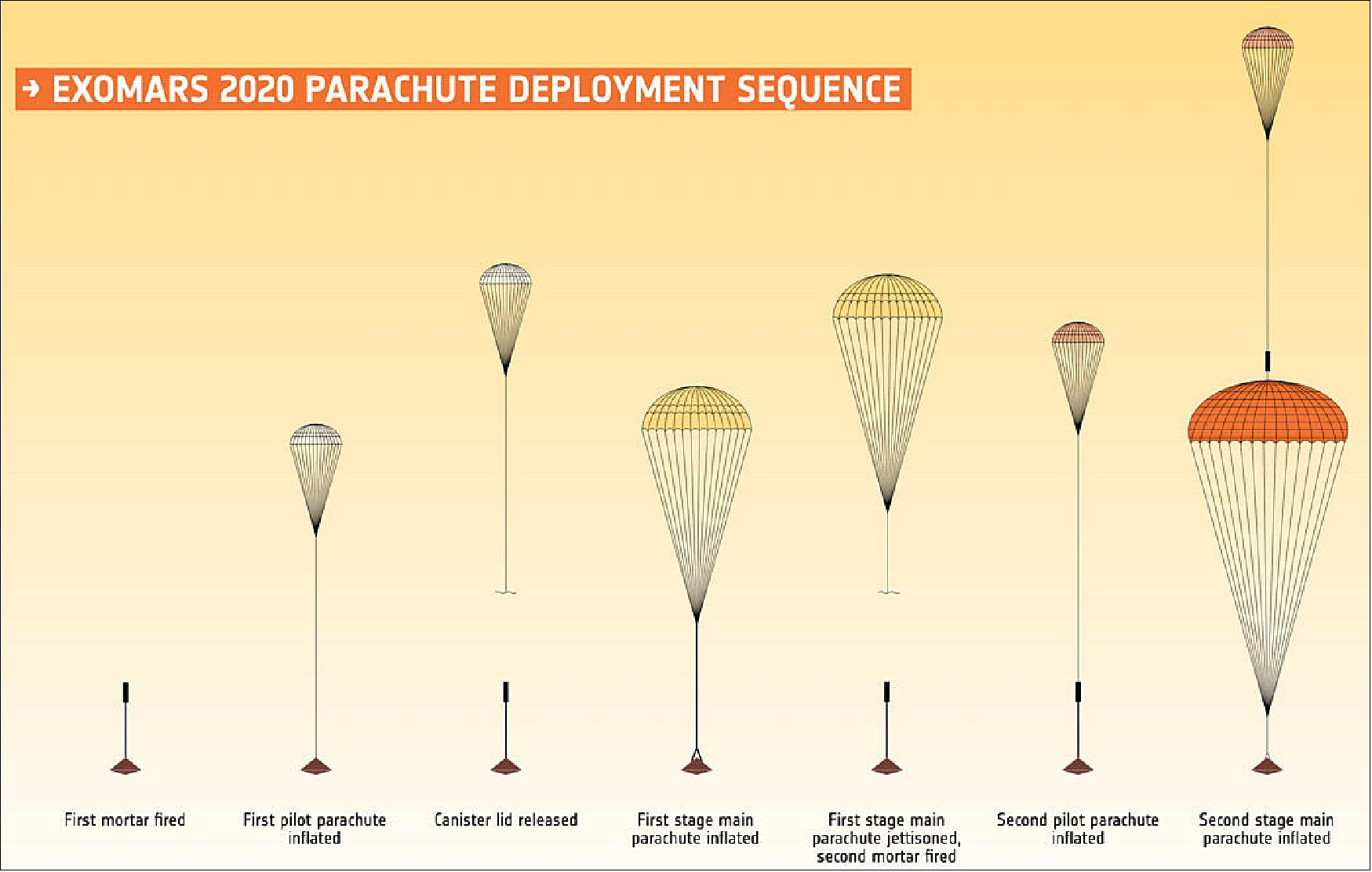

- After a nearly nine-month interplanetary cruise, a descent module containing the rover and platform will be released into the martian atmosphere at a speed of 21 000 km per hour. Slowing down requires a thermal shield, two main parachutes – each with its own pilot chute for extraction – and a retro rocket propulsion system triggered 30 seconds before touchdown. The 15 m-wide first stage main parachute opens while the descent module is still travelling at supersonic speeds, and the 35 m-wide second stage main parachute is deployed at subsonic speeds.

- Adjusting and testing the ExoMars parachutes has been a priority following a series of unsuccessful drop tests in 2019 and 2020. The first high altitude success took place in June 2021 with the flawless deployment of the first main parachute provided by Airborne Systems.

- In that set of tests, the 35 m-wide second stage parachute provided by Arescosmo experienced one minor damage, likely due to an unexpected detachment of the pilot chute during final inflation, but it still decelerated the drop test vehicle as expected. In the intervening months the pilot chute attachment was changed, and Kevlar reinforcements were replaced with nylon on two rings in the parachute canopy to better match the same strength and elasticity of the parachute fabric, in order to reduce the risk of tearing.

- Adjustments to the parachute system are first tested on the dynamic extraction test rig at NASA/JPL to check how the release of the parachute from the bag occurs, as it would happen in the martian atmosphere. These tests can be repeated on a quick turnaround and reduce the risk of anomalies.

- High-altitude drop tests require complex logistics and strict weather conditions, making them difficult to schedule, and are often aborted at the last moment if the situation changes. The wind speed and direction at various altitudes has to be considered for a smooth ascent of the balloon and the on-ground recovery of the hardware given that the drop zone can only be accessed via helicopter, and must not fall over populated areas. There must also be no rain, clouds or fog, and the humidity must be such that condensation does not accumulate on the huge envelope of the 335 000 m3 balloon as this would cause a large quantity of water to fall on the drop test vehicle and its electronics.

- Once these requirements have been met and the green light given to inflate and launch the helium-filled stratospheric balloon, the drop test vehicle is lofted to an altitude of 29 km. Following release from the balloon, the pilot chute deployment is initiated, which in turn pulls the main parachute from its doughnut bag.

- “Everyone working on this campaign – both on site and off – had to wait a long time in this launch window for the right weather conditions, but we are delighted with the outcome,” says Thierry. “After recovering the parachutes we observed only a handful of very tiny and insignificant 1-2 cm sized tears and friction searing on the two parachute canopies. We can certainly fly as-is without any concern, but adjustments are still possible, and we will carefully scrutinize the results of the next tests early next year.”

- The parachutes are just one element of this complex mission, which, after launch, will see a carrier module transport the rover and surface platform to Mars inside a descent module. Significant progress has been made across many areas of the mission in the last months, as the functional testing phase draws to a close and attention shifts to the launch campaign in Baikonur.

- “Thanks to the incredible efforts of all our partners, we are wrapping up loose ends in this highly complex mission to ensure we have a robust mission to fly to Mars,” adds Thierry. “In parallel, launch campaign preparations are proceeding at full steam and we’re looking forward to ship the spacecraft modules and ground support equipment to Baikonur in late March and early April. An exciting year is to come.”

- All parachute system qualification activities are managed and conducted by a joint team involving the ESA project (supported by the Directorate of Technology, Engineering and Quality), Thales Alenia Space Italy (ExoMars prime contractor, in Turin), Thales Alenia Space France (parachute system lead, in Cannes), Vorticity in the UK (Parachute design and test analysis, in Oxford) and Arescosmo in Italy (parachute and bags manufacturing, in Aprilia). NASA/JPL-Caltech has provided engineering consultancy, access to the dynamic extraction test facility, and on-site support during these tests. The extraction tests are supported through an engineering support contract with Airborne Systems, who also provided NASA’s Mars 2020 parachutes, and by Free Flight Enterprises for the provision of parachute folding and packing facilities. Airborne Systems is also providing parachute design and manufacturing services since 2021.

- Near Space Corporation provide the balloon launch services in Oregon. The Swedish Space Corporation Esrange facility provides the balloon launch services in Kiruna.

• December 3, 2021: The ExoMars rover used in the Earth-based Mars Terrain Simulator makes escaping from a sand trap look easy in this exercise. 15)

- The rover initially has its front two wheels almost completely buried in sand, but easily escapes using its unique wheel-walking mode.

- Rovers on Mars have previously been caught in sand, and turning the wheels dug them deeper, just like a car stuck in mud or snow. To avoid this, the ExoMars rover Rosalind Franklin – and its replica – has a unique wheel walking locomotion mode. Similar to leg movements, wheel-walking combines motions of the deployment actuators (the legs) with the rotation of the wheels to progress without slippage. This motion gives very good traction in soft soils and high slopes, such as dunes.

- “We hope to never need to use wheel walking on Mars to escape dangerous sand traps, but we are glad to have such functionality to potentially safeguard the mission,” comments Luc Joudrier, ESA ExoMars Rover Operations Manager. “From a rover operational point of view, this is really our insurance again difficult terrains.”

- In the test run seen here, the back wheels drag once the front four wheels have gained good traction on firmer terrain. The reason is that the wheel-walking sequence tested here has rather been optimized for climbing steep slopes with loose soils. In this sequence of commands, a short rotation of the wheel follows each movement of the legs. This is to anchor the wheels, digging them a little bit into the soil, before moving the rest – like when you climb a slope with snow and firm up each step before making a new one. On firmer soils, the anchoring rotation is not as effective (it can create the dragging effect) and therefore can be excluded from the command sequence.

- The activity took place in the Mars Terrain Simulator at the Rover Operations Control Centre at the ALTEC premises, at Thales Alenia Space facilities in Turin, Italy in November 2021. It is from here that rover science operations will take place once Rosalind Franklin lands on Mars in June 2023. In the meantime, the facility is being used for training rover operators and simulating science operations that will be expected in the main mission.

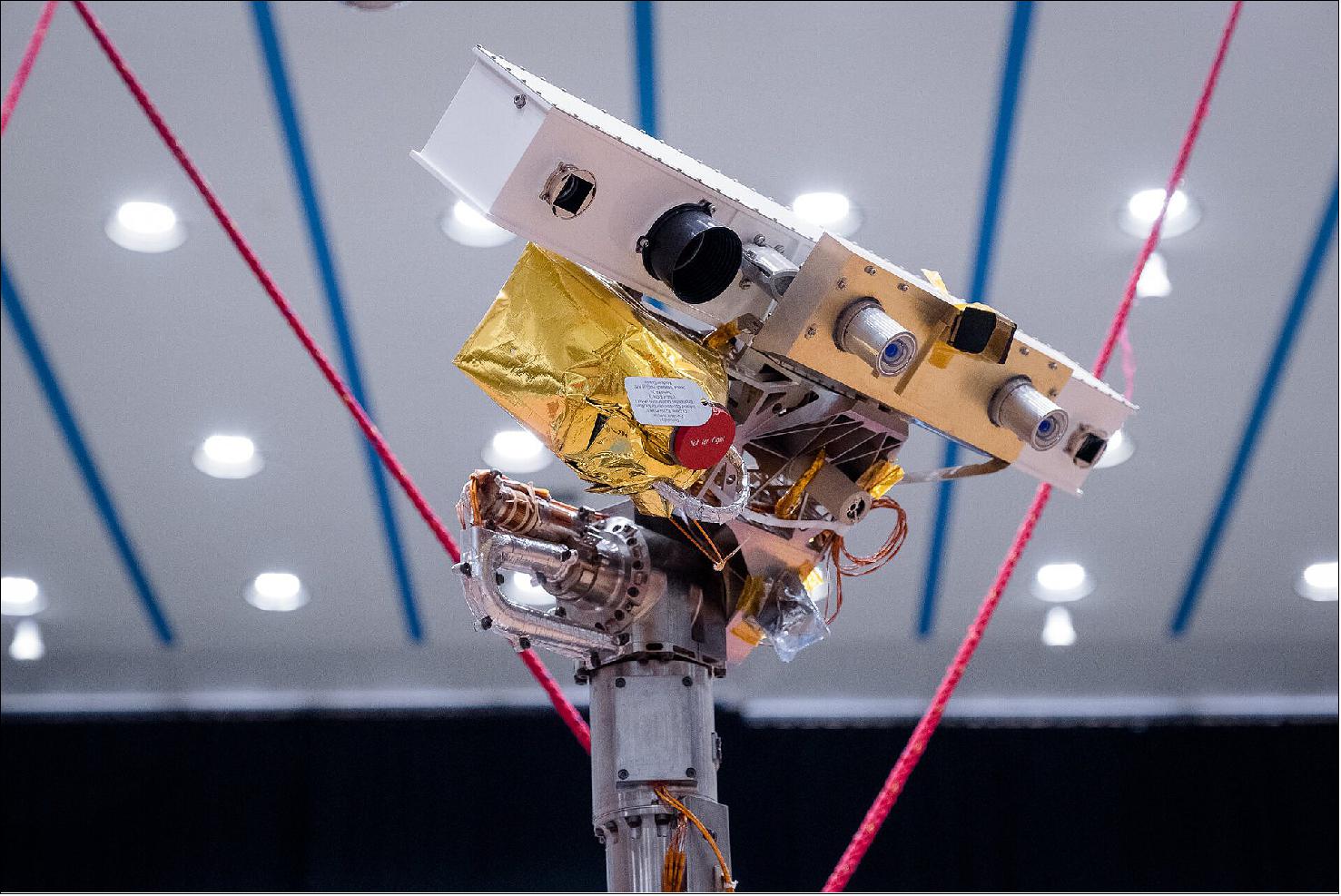

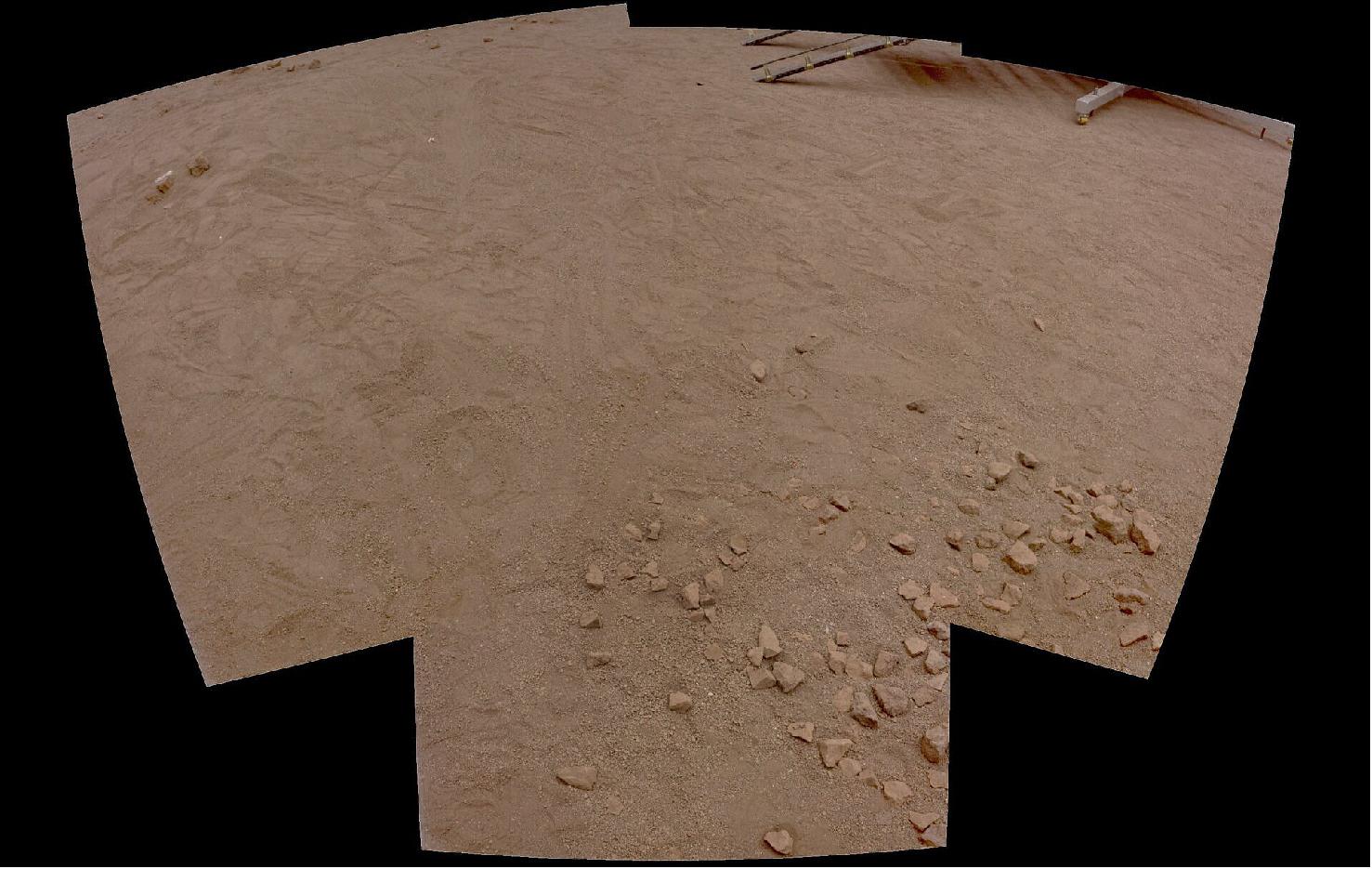

• November 4, 2021: From panoramas to close-ups, from 3D maps to a wheel selfie, the Earth-bound twin of ESA’s Rosalind Franklin rover is testing the wide range of photo settings that will deliver the greatest science possible during the ExoMars mission on the Red Planet. 16)

- The scientific eyes of the rover are set on the Panoramic Camera suite known as PanCam. The replica atop the mast of the Ground Test Model rover is achieving a level of detail similar to what is expected from Rosalind Franklin in 2023.

- The target over the last few months has been the reddish and grainy, sometimes rocky surface of the Mars Terrain Simulator at the ALTEC premises in Turin, Italy.

- “Since we will be looking for water and life on Mars, testing Rosalind Franklin’s main cameras is particularly important in the search for water-rich minerals,” explains Andrew Coates, PanCam principal investigator and Professor at the UCL Mullard Space Science Laboratory in the UK.

Science on Top

- Engineers have packed as much science as they could into the camera system.

- The two wide-angle cameras (WACs) are set 50 cm apart and form a stereo pair that images what is in front of the rover from a vantage point about two meters above the ground. Scientists create 3D pictures and depth maps by overlaying simultaneous snapshots.

- “Besides plotting routes where the rover can go, these cameras help us do geology and atmospheric science,” says Andrew.

- The High Resolution Camera (HRC) has eight times the resolution of the wide-angle cameras to closely examine rock texture and grain size in color.

- This powerful camera “will help us investigate very fine details in outcrops, rocks and soils, find the most promising spots to drill, and take images of the samples before they are sent to the rover’s laboratory,” says Nicole Schmitz, PanCam co-principal investigator responsible for the high-resolution camera at the DLR Institute of Planetary Research, Germany.

- Mounted below is the infrared spectrometer (ISEM) that analyses the geochemistry of the rocks. HRC and ISEM are a well-matched couple. They are co-aligned, so that scientists can see in the HRC images where ISEM took its measurements.

Rainbow Eyes

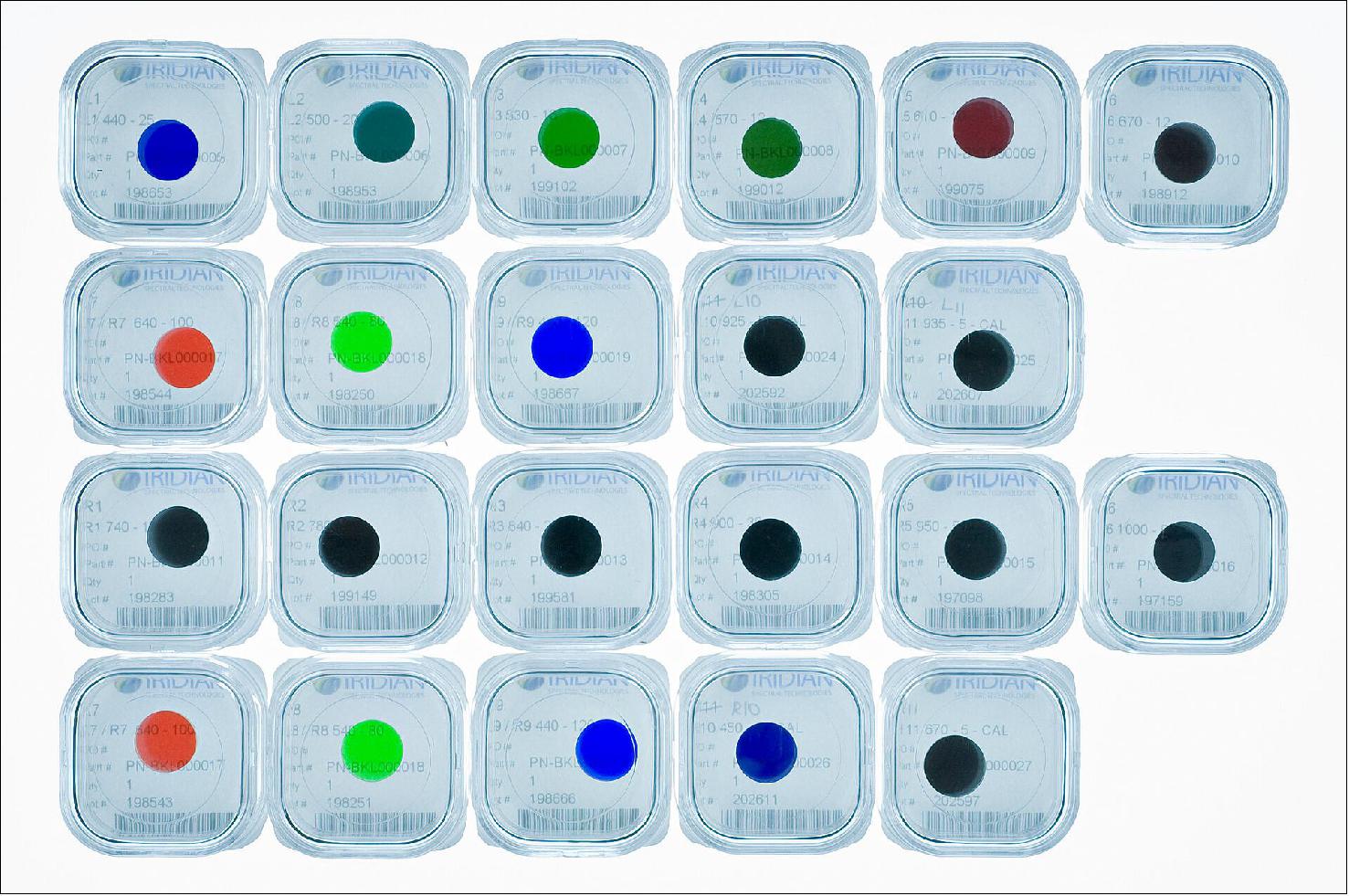

- Humans and smartphones can only see colors in visible light. PanCam can ‘see’ in 19 colors, in the visible and near infrared wavelengths.

- Each of the wide-angle cameras has a filter wheel with 11 positions to look at the colors of the rocks and the martian sky.

- This special carousel will allow the rover to stare at the Sun, find the amount of dust in the atmosphere and measure the water vapor content during sunsets on Mars.

- A calibration target mounted on the rover’s solar array top deck, comprising a palette of stained glass similar to that of church windows, will help PanCam get its colors right.

Mars-proof

- PanCam can withstand much harsher conditions than smartphone cameras on Earth. The hardware can cope with extreme temperatures, from zero degrees during the day down to –120 º Celsius during the cold martian nights. The sensors are also resistant to the high radiation environment during the journey to Mars and on the surface of the planet.

- “It was challenging to build a robust enough camera with adjustable focus to take high resolution images of very close and far away targets,” says Nicole.

- Rosalind Franklin can also take a look at herself – a small spherical mirror close to one of the rover’s wheels can be used to get a view underneath the rover. The Rover Inspection Mirror, mounted near a rover wheel, will enable PanCam to capture images from underneath the rover.

- There is yet another camera which will come in to play for martian shots in upcoming tests. The Close-Up Imager, CLUPI, will provide detailed views of the soil that is churned out by the drilling action. When the drill is in ‘stowed’ position this camera can also take photos of the landscape to the side of the rover.

• October 29, 2021: The Rosalind Franklin rover that will search for life on Mars has completed an important bakeout to help clean the rover from organic molecules from Earth. 17)

- An additional analysis following the bakeout will be completed at a later date. That is, the rover’s Mars Organics Molecule Analyzer (MOMA), one of the instruments inside the rover’s analytical laboratory ultra-clean zone that will be used to determine if signs of life are present in the martian soil, will determine the chemical background in the rover’s laboratory by performing a measurement using an empty oven. Once on Mars, MOMA’s tiny ovens will host crushed soil samples that will be heated to allow the resulting vapor and gases to be analyzed with gas chromatography techniques to sniff out traces of organic compounds. The ‘sniff’ of the empty oven following the Earth-based bakeout will establish the background footprint against which future measurements on Mars can be compared.

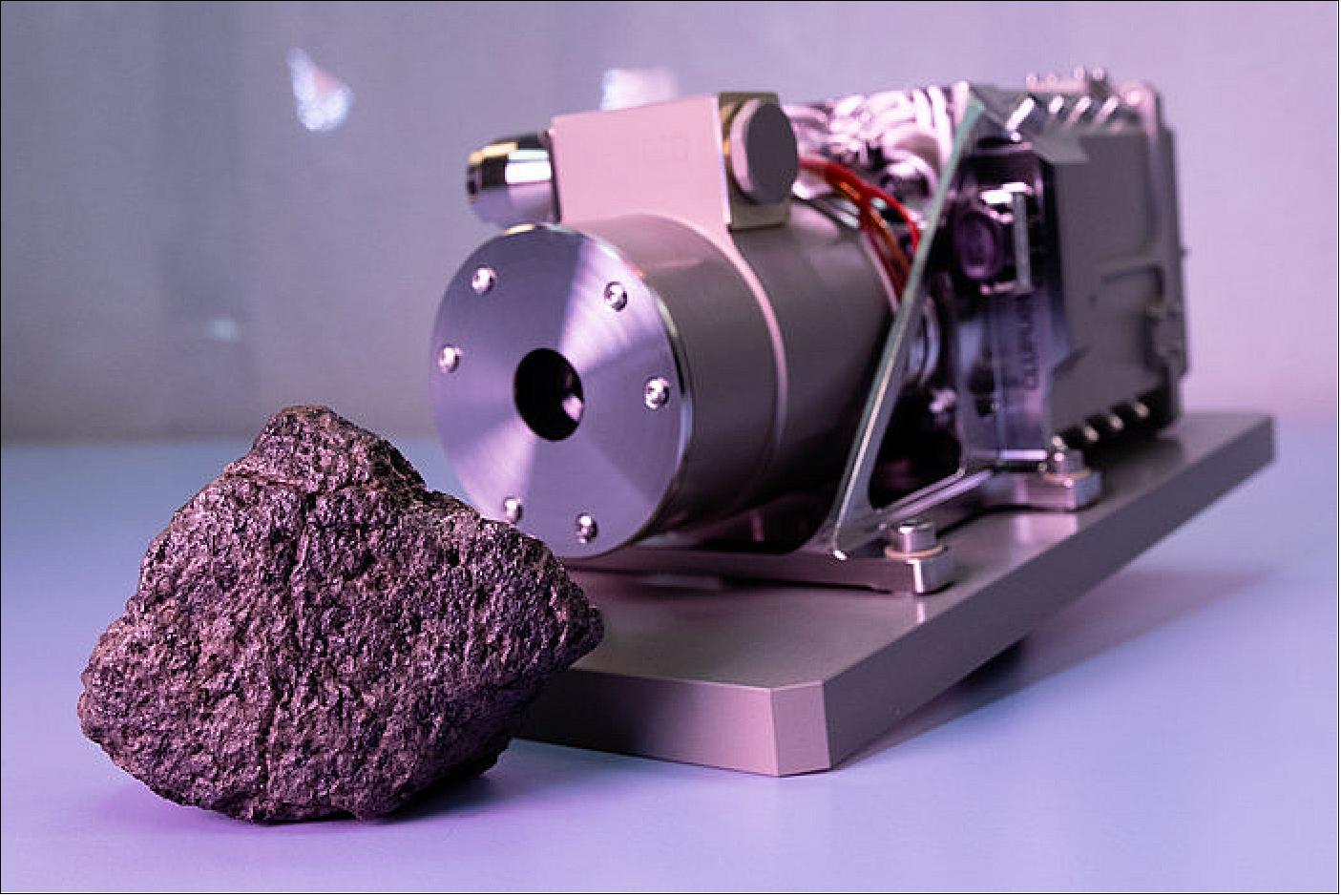

- The rover is equipped with a unique drill that will bore down to 2 m below the martian surface and return samples for analysis. In the video, the rover is seen with its drill box in horizontal stowed position at the front. The drill tool also hosts a miniaturized spectrometer (Ma_MISS) to analyze the inner surface of the borehole, and a close-up imager (CLUPI) that will look at the drill fines and core sample before it enters the rover’s laboratory.

- Different instruments will work together to analyze the samples inside the rover. In addition to MOMA, the MicrOmega instrument will use visible and infrared light to characterize minerals in the samples, and a Raman spectrometer will use a laser to identify mineralogical composition.

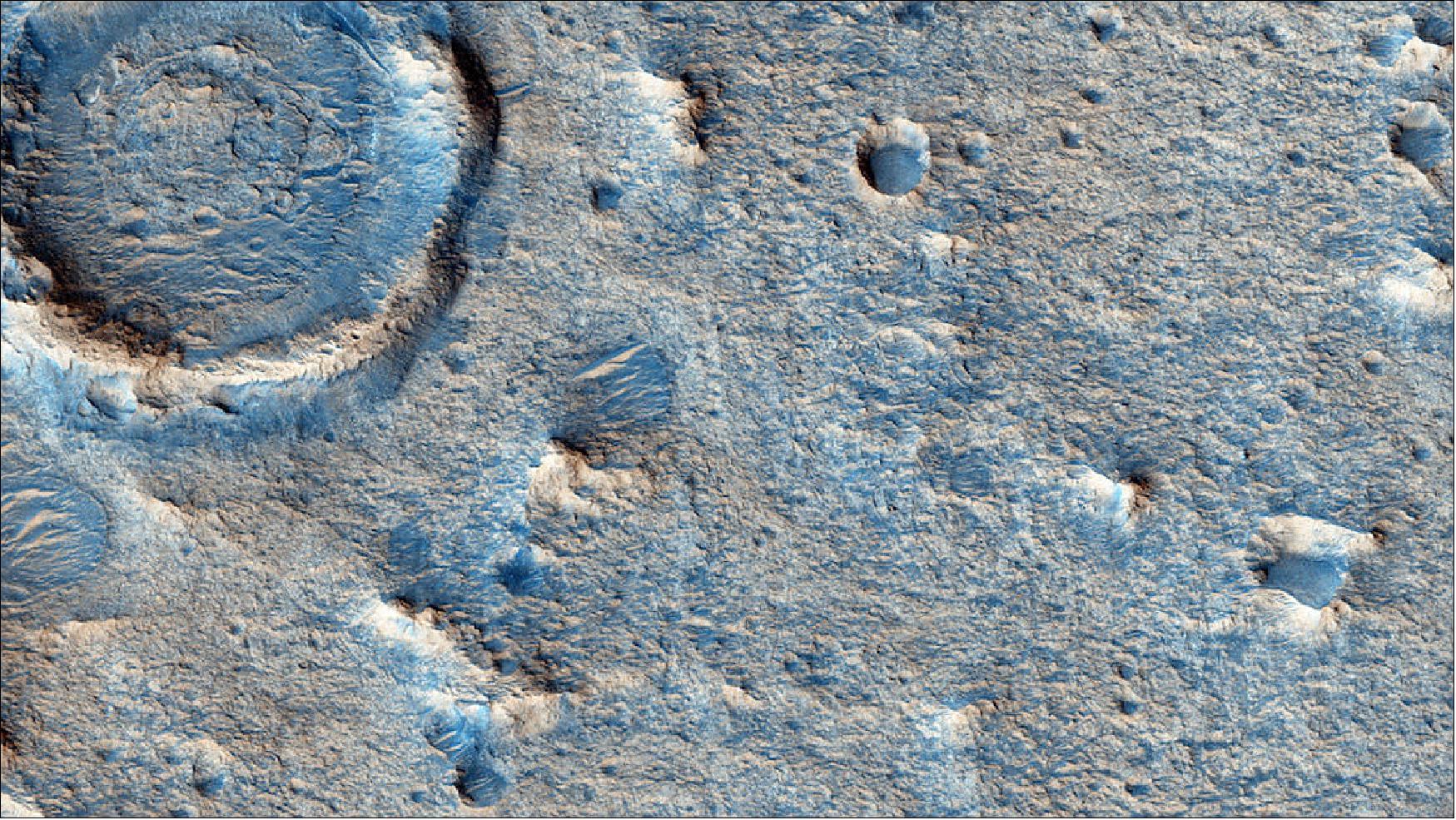

- Using its panoramic and high resolution cameras and ground-penetrating radar, the ExoMars rover will seek out the most promising locations to drill, and to better understand the geological context of the Oxia Planum region that it will explore.

- Following completion of the bakeout, the thermo-vacuum chamber was re-pressurized and opened, and the rover prepared for its return journey to Thales Alenia Space in Turin. There, readiness for launch will continue until it ships to the launch site next year.

- Parts of the video are shown as timelapse.

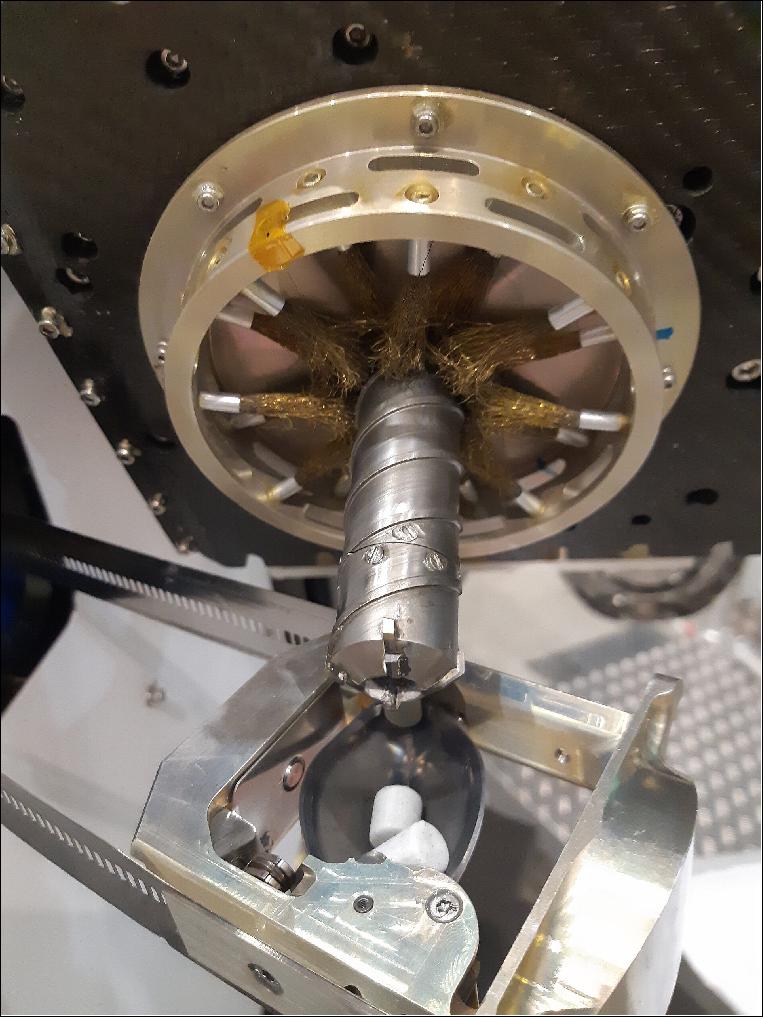

• September 15, 2021: ESA’s Rosalind Franklin twin rover on Earth has drilled down and extracted samples 1.7 meters into the ground – much deeper than any other martian rover has ever attempted. 18)

- The successful collection of soil from a hard stone and its delivery to the laboratory inside the rover marks a promising milestone for the ExoMars 2022 mission.

- “The long-awaited success of the ExoMars drill on Earth would be a first in Mars exploration,” says David Parker, ESA’s director of human and robotic exploration. The deepest any drill has dug on the Red Planet to date is 7 cm.

- The Rosalind Franklin rover is designed to drill deep enough, up to two meters, to get access to well-preserved organic material from four billion years ago, when conditions on the surface of Mars were more like those on infant Earth.

Drill Operations

- Rosalind Franklin’s twin has been drilling into a well filled with a variety of rocks and soil layers. The first sample was taken from a block of cemented clay of medium hardness.

- Drilling took place on a dedicated platform tilted at seven degrees to simulate the collection of a sample in a non-vertical position. The drill acquired the sample in the shape of a pellet of about 1 cm in diameter and 2 cm long.

- Rosalind Franklin’s drill retains the sample with a shutter that prevents it from dropping out during retrieval. Once captured, the drill brings the sample to the surface and delivers it to the laboratory inside the rover.

- With the drill completely retracted, the rock is dropped into a drawer at the front of the rover, which then withdraws and deposits the sample into a crushing station. The resulting powder is distributed to ovens and containers designed to perform the scientific analysis on Mars.

- “The reliable acquisition of deep samples is key for ExoMars’ main science objective: to investigate the chemical composition —and possible signs of life— of soil that has not been subjected to damaging ionizing radiation,” says ExoMars project scientist Jorge Vago.

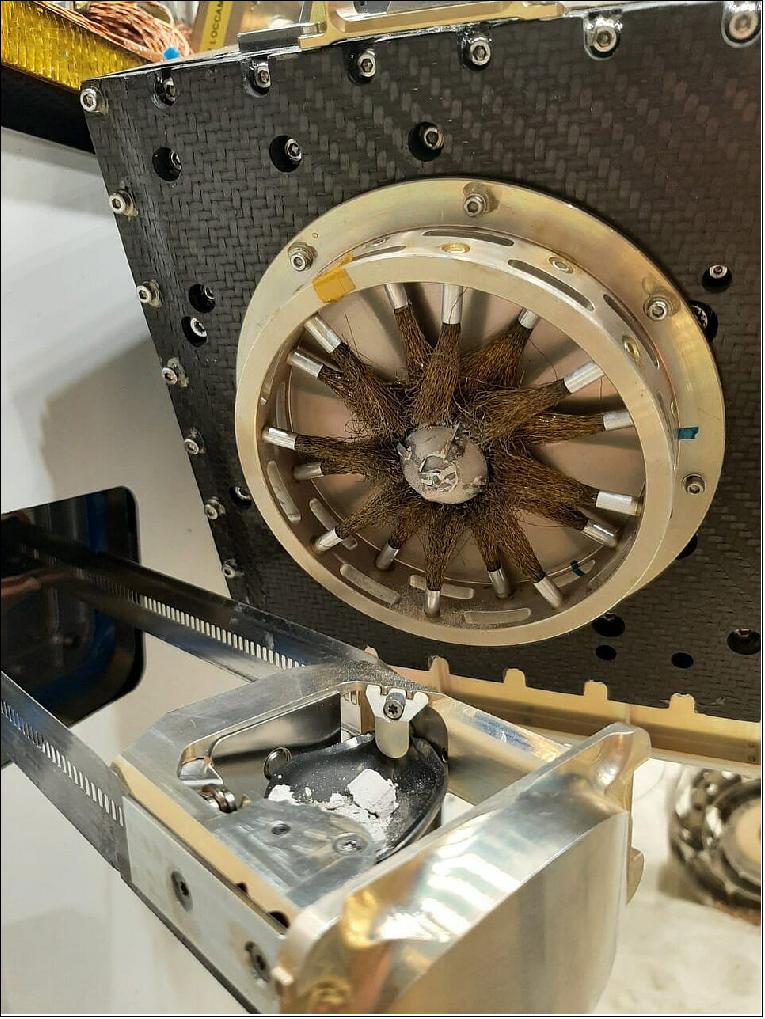

A Unique Drill for Mars

- The ExoMars drill is an assembly of mechanisms that rely on an automated choreography of tools and mounting rods. “The design and construction of the drill has been so complex that this first deep drilling is an extraordinary achievement for the team,” says Pietro Baglioni, ExoMars rover team leader.

- Rosalind Franklin’s drill works on rotation. A series of tools and extension rods are fitted to form a ‘drill string’ and can reach the full 2 m length when all are connected.

- The drill can penetrate the ground at 60 rotations per minute, depending on the consistency of the soil. Digging into sandy or clay solid materials could take between 0.3 and 30 mm per minute.

- The drill has also a two-degree of freedom positioner that allows it to discharge the sample at the right angle into the rover laboratory.

• September 3, 2021: The ExoMars team have performed important parachute drop tests as crucial preparation for a safe touchdown on Mars in 2023. The European Rosalind Franklin rover will search for signs of past life beneath the surface of Mars with its unique two meter drill and onboard laboratory. The Russian surface science platform Kazachok will study the environment at the landing site. Landing on Mars is always a challenging endeavor and all possible parameters are taken into account. 19)

• July 2, 2021: After several weeks of bad weather and strong winds, the latest pair of high-altitude drop tests of the ExoMars parachutes took place in Kiruna, Sweden. 20)

- Each high altitude drop test saw a dummy descent module lofted to an altitude of 29 km by a stratospheric balloon inflated with helium. Following release, the pilot chute extraction initiates with a controlled extraction of the main parachute from the doughnut bag.

- The first test focused on validating the Airborne Systems backup supersonic parachute – the first drop test for this parachute in this ExoMars test campaign.

- These tests took place after several weeks of bad weather in Kiruna, and follow the high-altitude drop tests in 2019, during which critical damage to both parachute canopies was observed.

- After a nine-month interplanetary cruise, a descent module containing the rover and platform will be released into the martian atmosphere at a speed of 21,000 km/hr.

- Slowing down requires a thermal shield, two main parachutes – each with its own pilot chute for extraction – and a retro rocket propulsion system triggered 20 seconds before touchdown. The 15 m-wide first stage main parachute opens while the descent module is still travelling at supersonic speeds, and the 35 m-wide second stage main parachute is deployed at subsonic speeds.

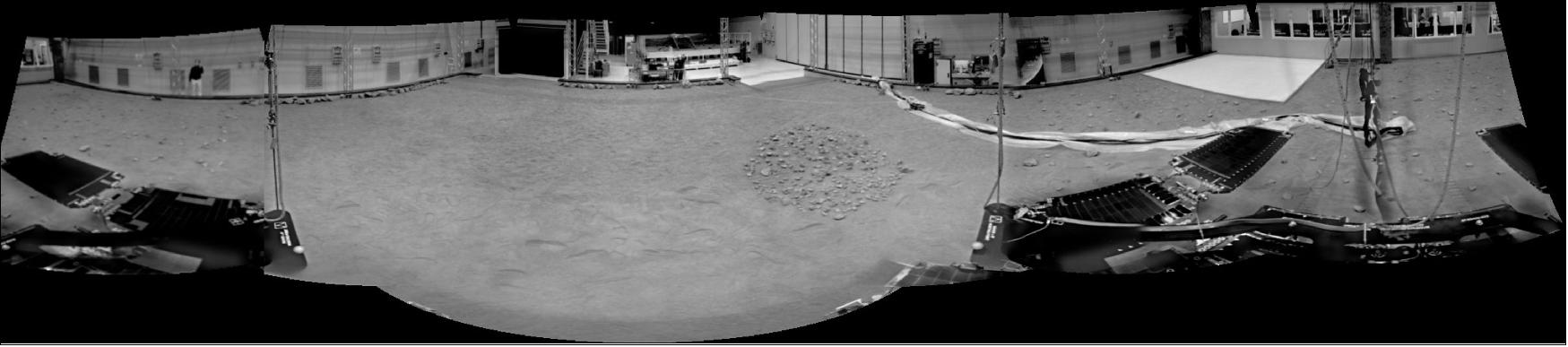

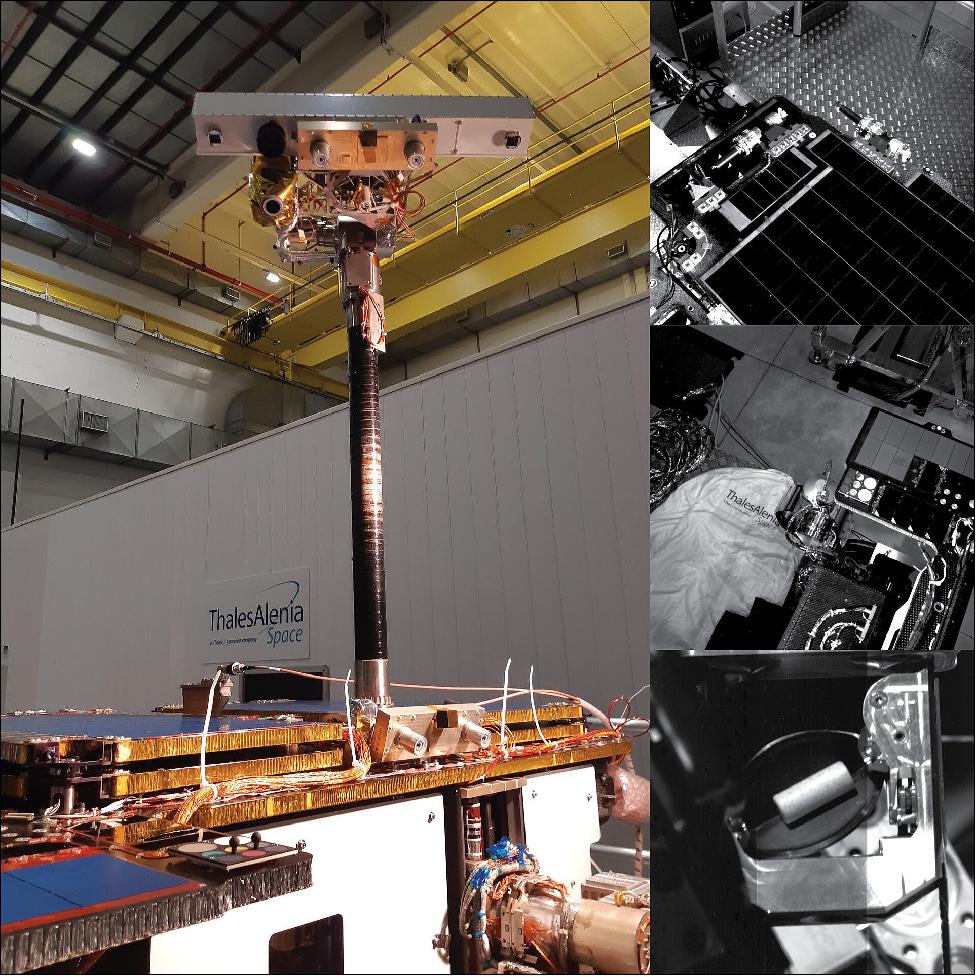

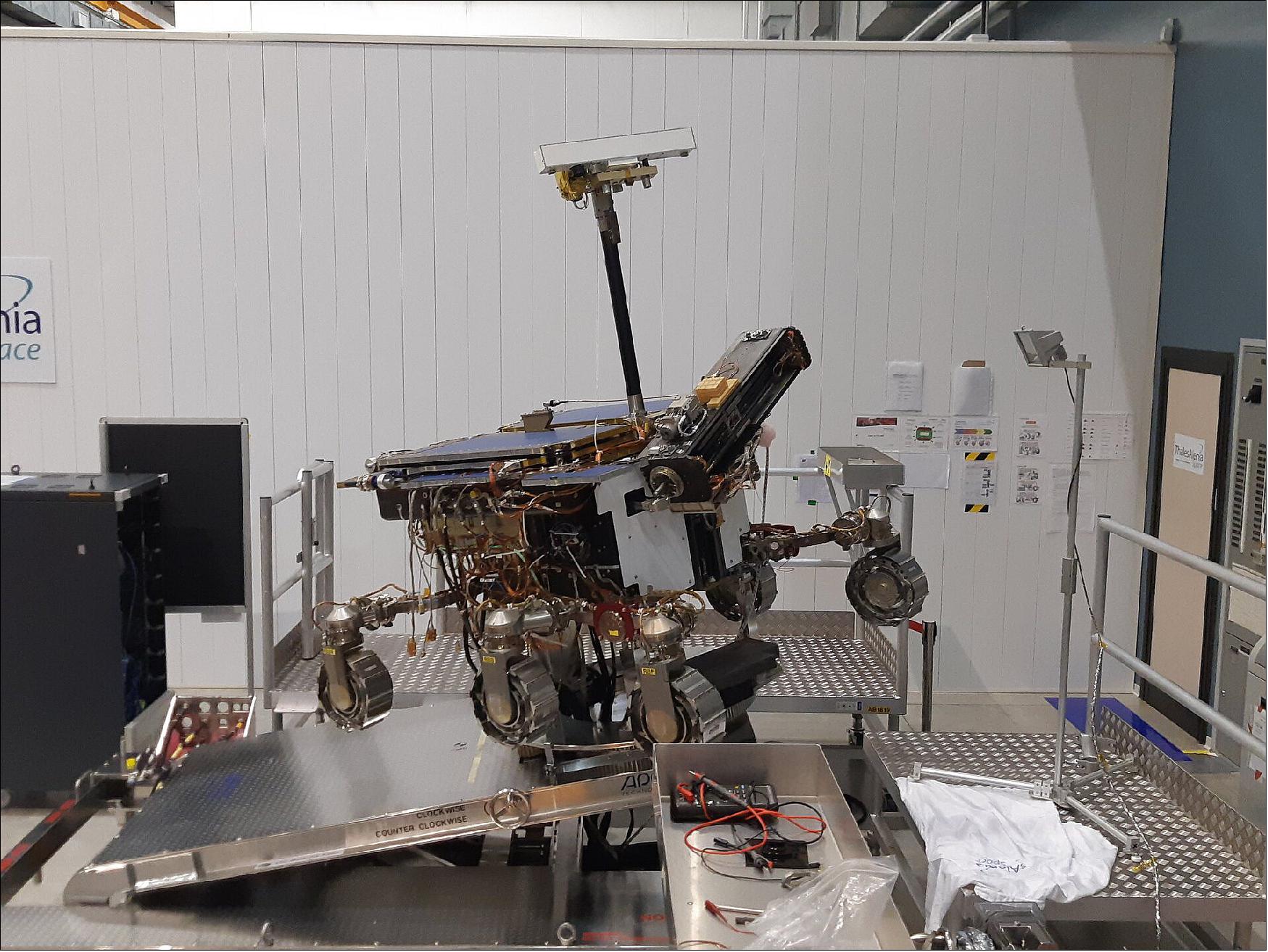

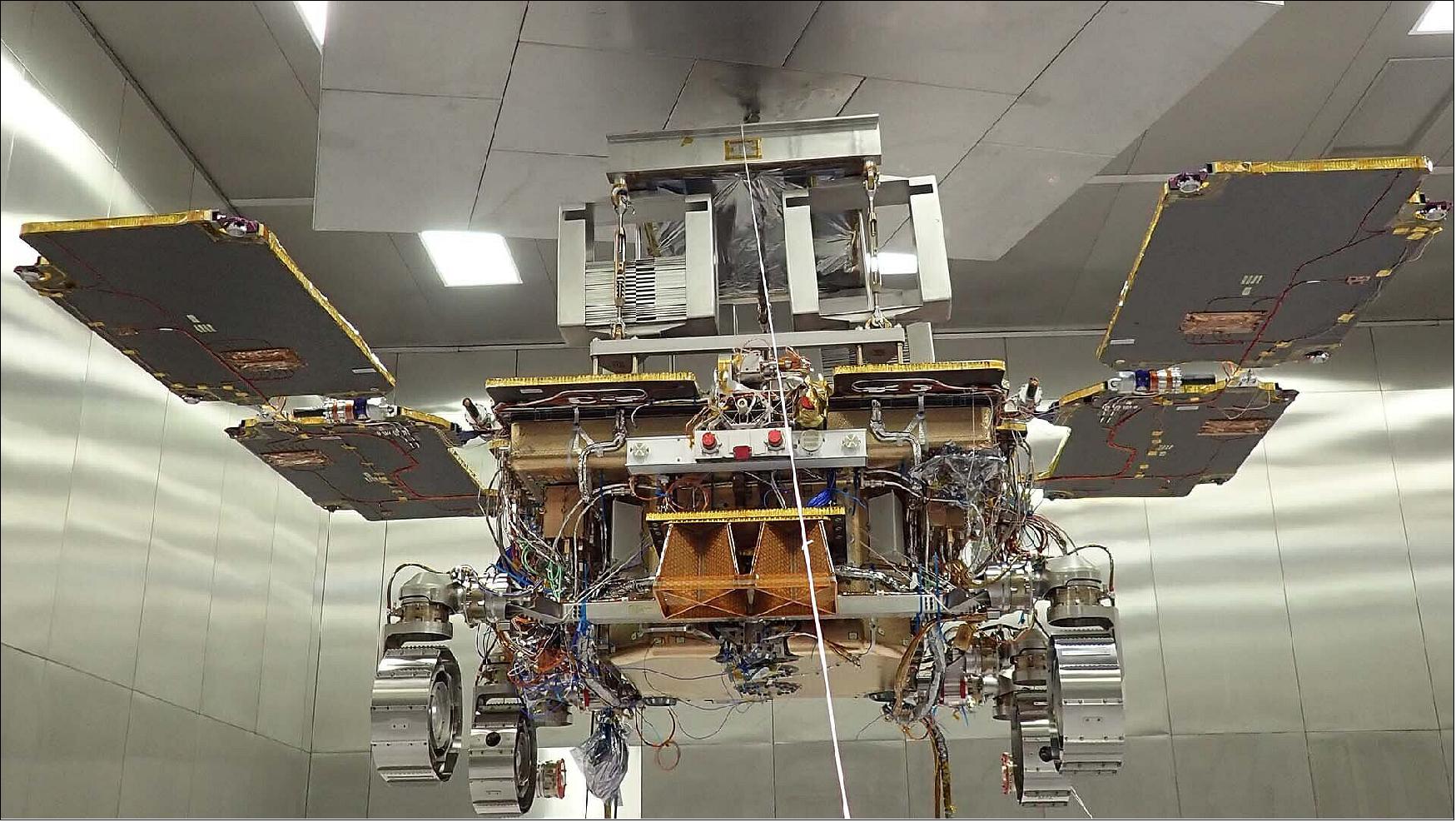

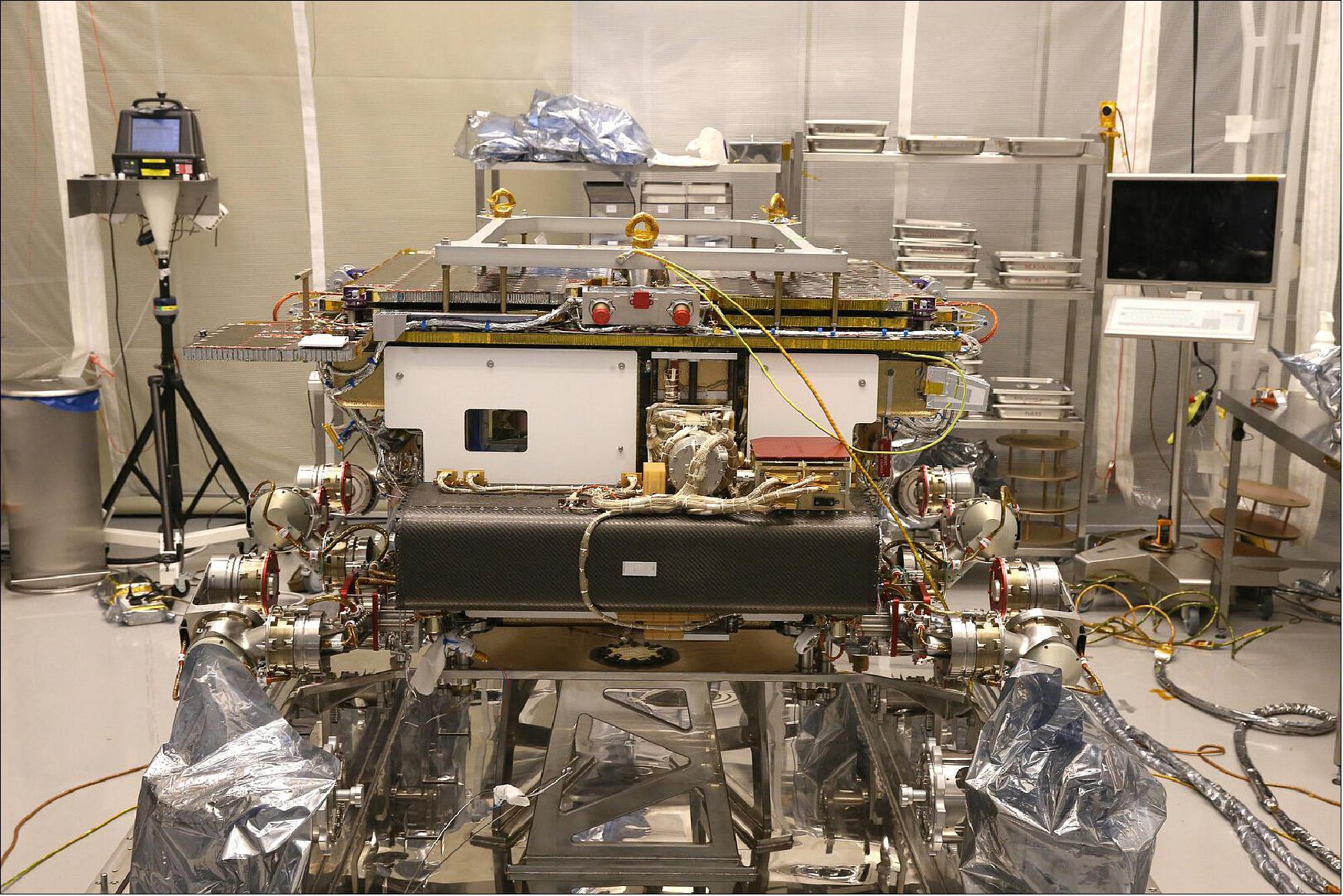

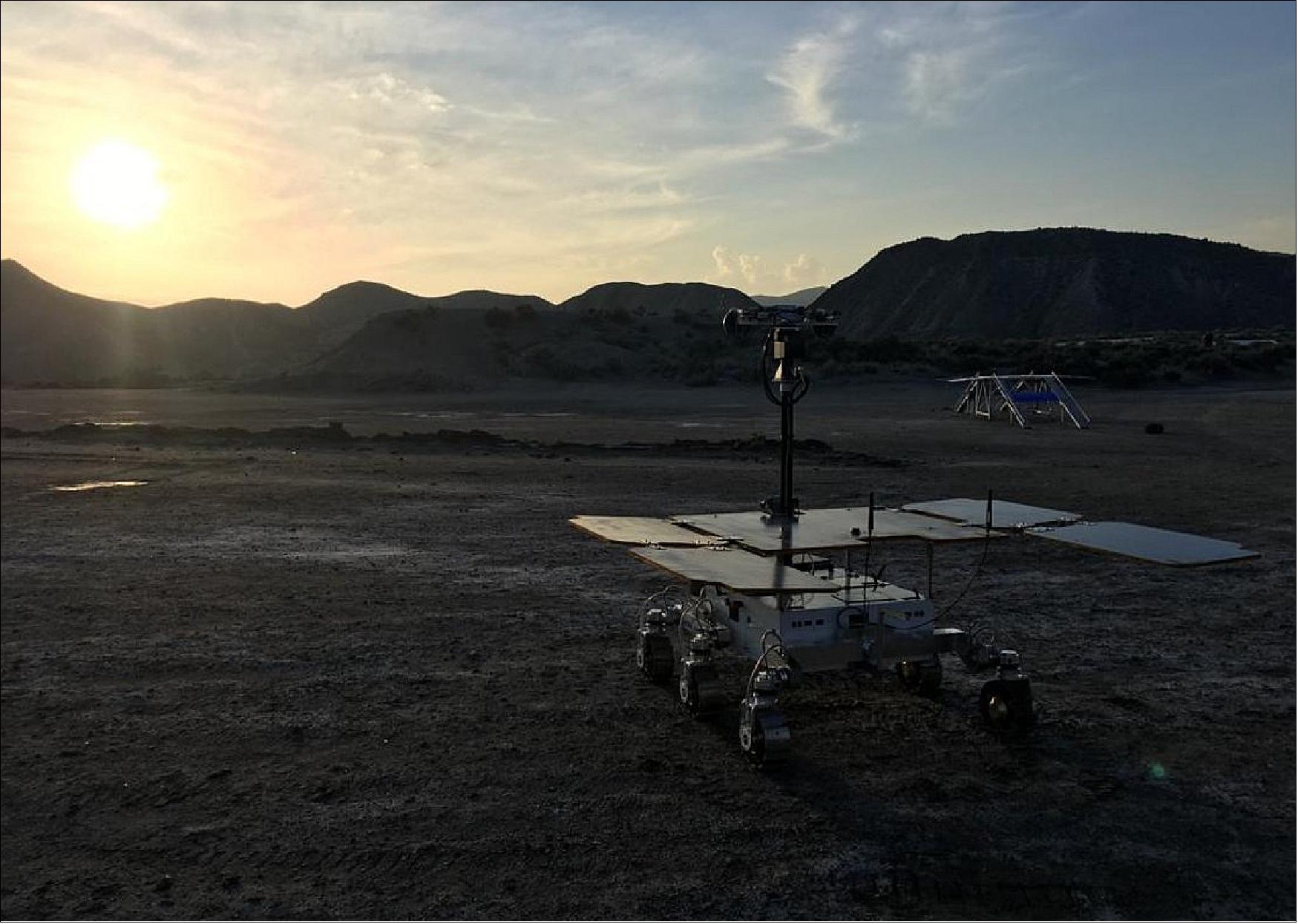

• June 4, 2021: The replica ExoMars rover that will be used in the ROCC (Rover Operations Control Centre) to support mission training and operations is fully assembled and has completed its first drive around the Mars Terrain Simulator at ALTEC, in Turin, Italy. 21)

- The rover ‘Ground Test Model’ (GTM) will play a critical role in the coming months as rover operators prepare for Rosalind Franklin’s arrival in Oxia Planum on Mars in June 2023.

- The GTM already completed important commanding tests while stationary in the Thales Alenia Space cleanroom, and now it has been fully assembled in the Mars Terrain Simulator.

- To best represent what the real Rosalind Franklin rover will experience on Mars, the GTM is supported by a device to recreate the martian gravity level. Mars gravity is about one-third of Earth’s so two-thirds of the rover’s 290 kg total mass is absorbed by the ‘Rover Unloading Device’ attached to the GTM from the ceiling of the test area.

- Rover operators will rehearse numerous activities with the replica rover, from moving across different terrain to deploying its science instruments.

- The first tests were simple driving activities: moving over different surfaces, tackling a side slope, small hill, and boulder-strewn terrain. On top of the hill, the rover was also commanded to take a panoramic image sequence.

- The test paves the way for more advanced activities in the coming months. For example, while the first driving test was executed by following direct drive commands, upcoming is a trajectory control test: that is, the rover will automatically correct deviations induced by the topography and roughness of the terrain to stay within 20 cm of the commanded path. Later, more advanced autonomous driving functions will be tested whereby the rover will use onboard computing capabilities to assess the safety of the terrain on its own.

- The GTM will also be used in the coming weeks for drilling activities. The ExoMars rover is unique in Mars exploration in that it will be first to drill 2 m below the martian surface to retrieve samples for analysis in its sophisticated onboard laboratory. Underground samples are more likely to include biomarkers, since the tenuous martian atmosphere offers little protection from radiation and photochemistry at the surface. Understanding if life once existed on Mars is a key question in planetary science, and at the heart of the ExoMars program.

• May 21, 2021: A series of ground-based high-speed extraction tests confirm the readiness of a new and upgraded parachute and bag system for a high-altitude drop test in early June, part of critical preparations to keep the ExoMars 2022 mission on track for its next launch window. 22)

- The tests, conducted with NASA/JPL’s dynamic extraction test rig in California, USA, focused on demonstrating the readiness of new equipment developed by Airborne Systems, as well as verifying changes to the parachute and bag provided by Arescosmo.

- A series of clips from different angles and at different speeds showing parachute extraction tests for the ExoMars 2022 mission’s first main parachute using a NASA/JPL test rig powered by compressed air. The lid of the parachute assembly is pulled along a suspended cable at high speed while the end of the assembly is fixed to a wall. When the release mechanism is activated, the parachute bag is pulled away from the parachute at the target speed, mimicking the extraction as it will be on Mars. At the highest speeds, the tests enable the extraction to take place at more than 200 km/h.

- The ESA-Roscosmos ExoMars mission, with the Rosalind Franklin rover and Kazachok surface platform contained in a descent module, requires two main parachutes – each with its own pilot chute for extraction – to help slow it down as it plunges through the martian atmosphere. The 15 m-wide first stage main parachute will open while the descent module is still travelling at supersonic speeds, and the 35 m-wide second stage main parachute is deployed once at subsonic speeds.

- The latest round of extraction tests focused on the first main parachute provided by both companies. Arescosmo addressed open issues from previous unsuccessful tests: a new bag design and a revised approach to folding to avoid line-twisting upon extraction. The Airborne Systems parachute and bag also completed several rounds of development tests to validate the extraction process.

- “Both performed very well in the tests,” says Thierry Blancquaert, ESA ExoMars program team leader. “Close inspection showed that a few small areas in the parachute canopy had been subject to friction during the bag extraction process, reducing the strength of the fabric in these few places. Cross-examination with the video footage allowed the Airborne Systems team to pinpoint the moment the damage occurred and make modifications to the bag and packing of the parachute. This could be done with a remarkably quick turnaround of just a couple of days, to arrive at a successful result.”

- The parachute had originally been packed inside the bag around the central mortar that contains the pilot chute, such that upon extraction it unwrapped in a 360º fashion. Folding the band of the parachute in two layers, so that it first unfolds in one direction and then 180º in the other direction, proved to reduce the tendency of the canopy to experience friction incurred by wrapping around the mortar.

- The Airborne Systems first main parachute will now move forward for testing in its first high-altitude drop test scheduled at the start of June from Kiruna, Sweden. Two high-altitude balloons and dummy descent modules are available in the June window, which will see the descent vehicle dropped under the parachute from a stratospheric balloon at an altitude of about 29 km.

- For Arescosmos, the first main parachute will act as a back-up, and instead the focus for them will turn to the second main parachute. Upgrades made to this parachute and bag were already implemented and tested in dynamic extraction tests in December 2020, which included using stronger parachute lines and reinforced material around the parachute apex. For the upcoming high-altitude test, a slightly smaller sized pilot chute (3.7 m compared with 4.5 m previously) will also be implemented, aimed at reducing the energy – and therefore the friction – generated upon extraction of the second main parachute from its bag. This cannot be tested on the ground-based rig in advance, which is only focused on the main parachute extraction from its bag.

- Further ground-based dynamic extraction test slots are anticipated during August to prepare for another pair of high-altitude drop tests foreseen for October/November this year, from Oregon, USA. Further high-altitude test opportunities are also considered during the first half of 2022. Subsequent test configurations will largely depend on the outcome of the upcoming tests in Kiruna, although it is expected to repeat successful tests at least once more.

- High-altitude drop tests require complex logistics and strict weather conditions, making them difficult to schedule, while the ground tests can be repeated on a quick turnaround, buying significantly more time in the test campaign and reducing risk by allowing more tests to be conducted on a short time frame.

- “Our strategy of having two highly qualified teams working on the parachutes, together with the availability of the ground-test rig, is already paying off and we are ready and looking forward to the next high-altitude drop tests,” says Thierry. “Landing safely on Mars is a notoriously difficult task. Investing our efforts in this test strategy is an essential part of ensuring a successful mission when we arrive at Mars in 2023.”

- All parachute system qualification activities are managed and conducted by a joint team involving the ESA project (supported by Directorate of Technology, Engineering and Quality expertise), Thales Alenia Space Italy (prime contractor, in Turin), Thales Alenia Space France (PAS lead, in Cannes), Vorticity (parachute design and test analysis, in Oxford) and Arescosmo (parachute and bags manufacturing, in Aprilia). NASA/JPL-Caltech has provided engineering consultancy, access to the dynamic extraction test facility, and on-site support. The extraction tests are supported through an engineering support contract with Airborne Systems, who also provided NASA’s Mars 2020 parachutes, and by Free Flight Enterprises for the provision of parachute folding and packing facilities. Airborne Systems is also providing parachute design and manufacturing services since 2021.

- Near Space Corporation provide the balloon launch services in Oregon. The Swedish Space Corporation Esrange facility provides the balloon launch services in Kiruna.

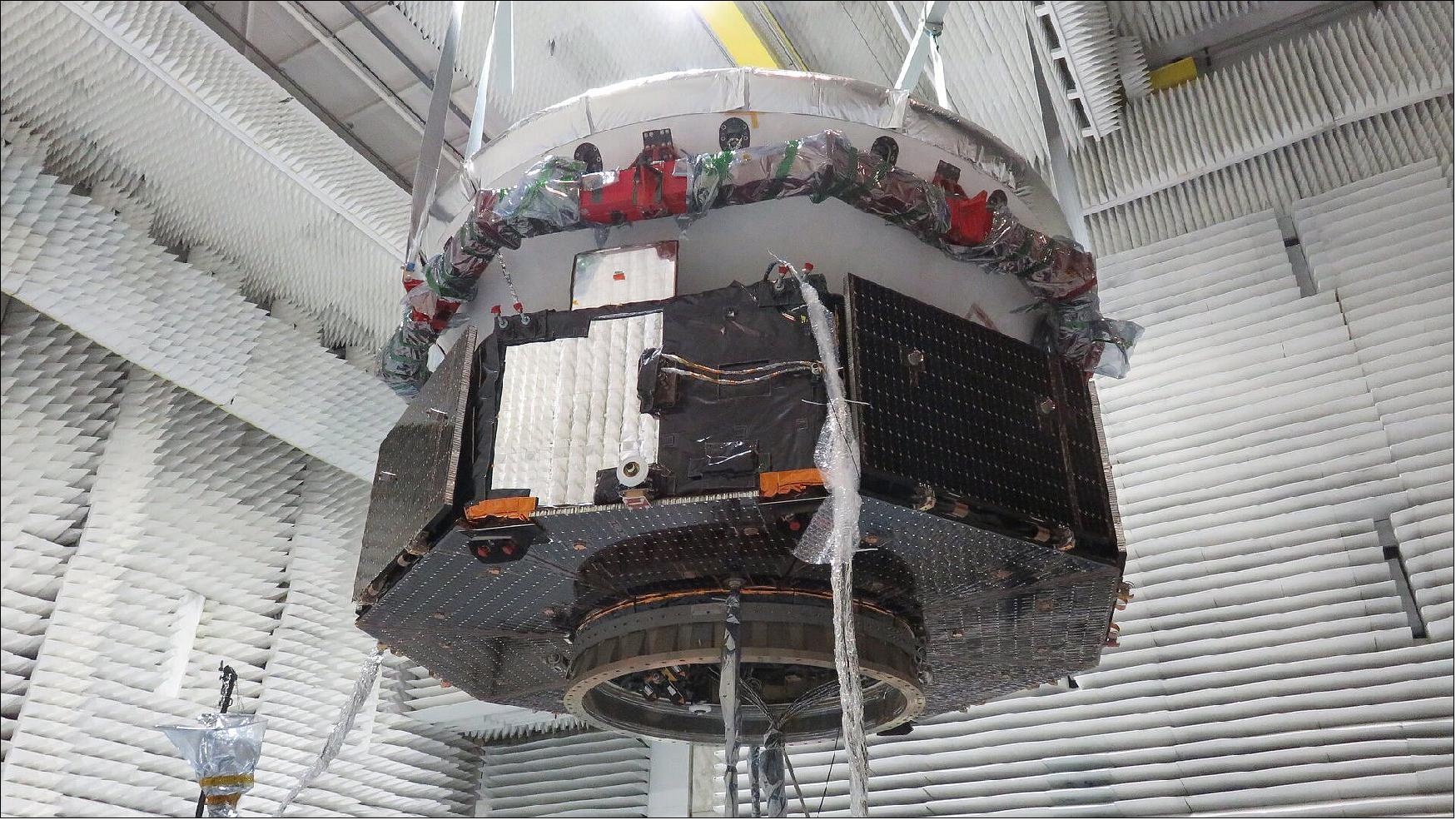

• March 5, 2021: ExoMars 2022 goes for a spin. 23)

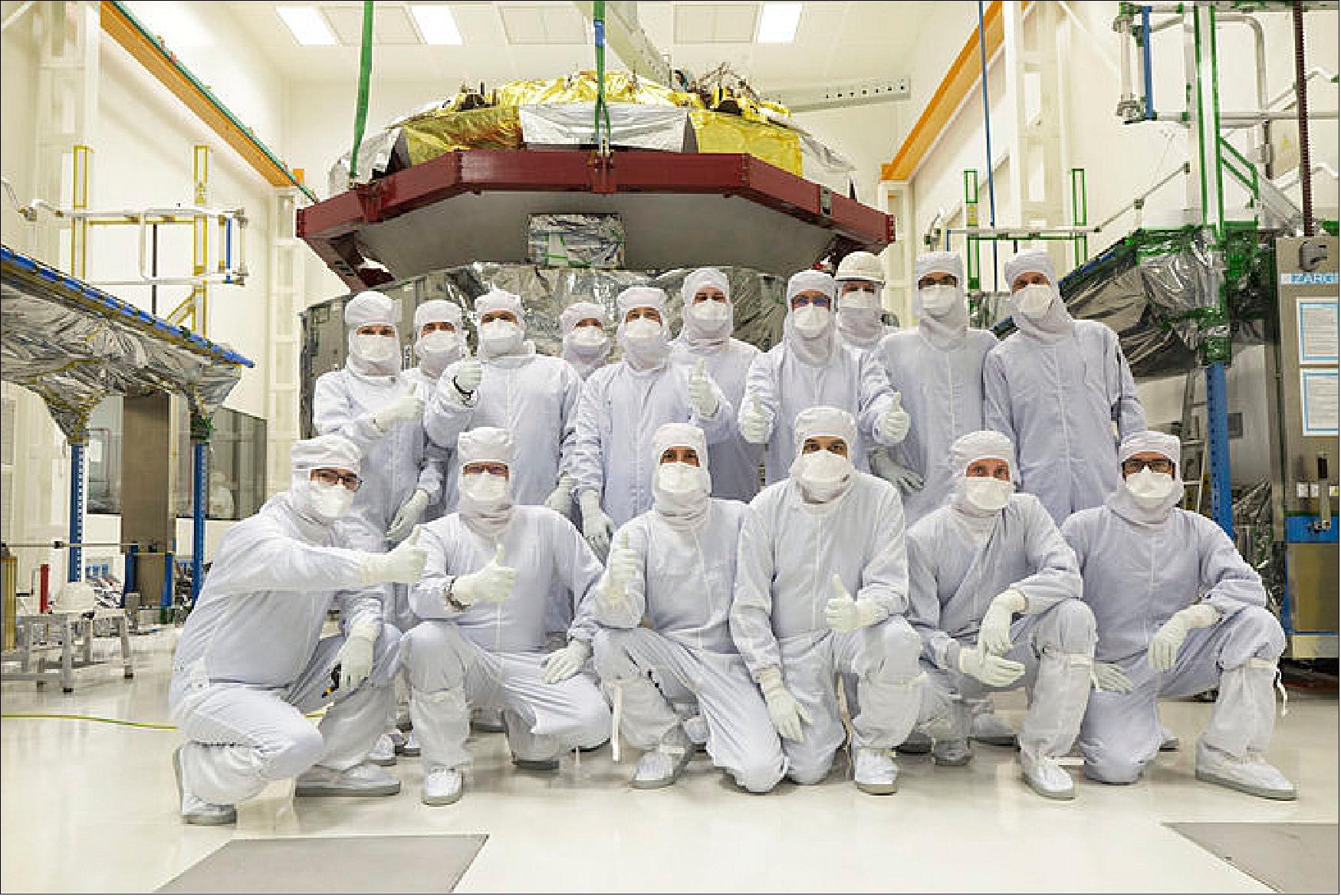

a) The full ExoMars 2022 mission comprising the carrier module, descent module, Kazachok surface platform and Rosalind Franklin rover have completed essential ‘spin tests’ in preparation for their journey to Mars.

b) Rosalind Franklin’s rover twin on Earth has executed trial science activities for the first time, including drill sample collection and close-up imaging.

c) A new parachute strategy has been adopted ahead of the next series of high altitude drop tests.

Balancing Act

- Essential preparation for the mission’s flight to Mars and plunge through the planet’s atmosphere is to ensure the spacecraft is perfectly balanced when spinning.

- The ExoMars 2022 mission comprises four main units: the ESA-led Rosalind Franklin rover and Roscosmos-led Kazachok surface platform that will perform science activities on the surface of Mars, the descent module in which they are encapsulated, and the carrier module that will transport them from Earth to Mars following launch.

- The spacecraft comprises the carrier module (the eight-sided structure), the descent module (the white module in the center) and the Rosalind Franklin rover and Kazachok surface platform, which are encapsulated inside the descent module. — The spacecraft composite was subjected to a spin up to 30 rpm, corresponding to a centrifugal acceleration of 2g at the outer edge of the heatshield.

- During the cruise to Mars the complete ‘spacecraft composite’ (comprising all four units) will be spinning at about 2.75 revolutions per minute, in order to stabilize itself on its trajectory. The dynamic balancing test checks that there are no imbalances that could induce wobbles in space that would require too much fuel to compensate. It is also important that the spacecraft is balanced so that it spins smoothly around its rotation axis, to keep its antenna pointed to Earth, so that a communication link is possible.

- Once the descent module is released close to Mars, about 30 minutes prior to atmospheric entry, the original spin rate is maintained until atmospheric effects take over, and when the first parachute is deployed. Complete despinning occurs once the propulsion system on the landing platform kicks in close to the surface of Mars.

- Therefore, two dynamic balancing tests were conducted: one test for the complete composite spacecraft, and one without the carrier module, for the descent module with rover and platform inside. In all the tests, which were conducted at Thales Alenia Space’s cleanroom facilities in Cannes, France, the actual flight modules were used.

- During the test with the spacecraft composite, the unit was subjected to a spin up to 30 rpm, corresponding to a centrifugal acceleration of 2g at the outer edge of the descent module’s heatshield.

- Upon completion of the environmental testing at Cannes, the spacecraft will return to Thales Alenia Space’s facilities in Turin, Italy, mid-March, for further functional testing.

Rehearsing Rover Science

- Meanwhile at the Rover Operations Control Centre (ROCC) in Turin, the Rosalind Franklin ‘ground test model’ completed an exciting milestone. While the replica rover is still stationary in the clean room, the operations team commanded it like they would when finally on the surface of Mars.

- “It’s really exciting to have used for the first time the ROCC chain of commands like we will during the real mission,” says Luc Joudrier, ESA’s ExoMars rover operations manager. “We defined the rover’s ‘Activity Plan’, sent it to the rover, and afterwards ingested and processed the data. It’s great to see the ROCC working like this.”

- One of the activities was to test Rosalind Franklin’s one-of-a-kind drill. It is the first time in Mars exploration that a rover will be able to retrieve soil samples down to 2 m underground, where ancient biomarkers may still be preserved from the harsh radiation on the surface, and deliver them to the onboard laboratory. In the recent exercise, the replica rover was commanded to deploy its drill with a dummy sample onboard, transporting it to the Analytical Laboratory Drawer. In reality, on Mars, a sophisticated laboratory will analyze the sample’s composition.

- The rover was also commanded to image the sample with its Close-Up Imager, situated at the bottom of the drill unit.

- The suite of high resolution panoramic cameras were also activated as part of an imaging calibration exercise.

- Soon the twin rover will move into the ROCC’s Mars Terrain Simulation to trial mobility commands and other functional tests. Rover operators and scientists will rehearse these simulations many times and focusing on different rover activities as part of their training between now and the mission arriving on Mars.

New parachute Test Strategy

- The two main parachutes that will help deliver the mission safely to the surface of Mars are scheduled for the next high altitude drop test in May/June this year, from Kiruna, Sweden. Following the high altitude drop test in November 2020, which saw some localised damages to both parachute canopies, a new way forward has been adopted.

- “We have revised our strategy to give us the best chance possible in qualifying the ExoMars parachutes before the end of this year in order to meet our 2022 launch window,” says Thierry Blancquaert, acting ExoMars program team leader. “We have therefore invited a second expert parachute manufacturer to contribute to the ExoMars program by providing us with additional canopies to use in the upcoming opportunities.”

- In addition to the parachutes from Arescosmo, newly manufactured parachutes from Airborne Systems, who helped deliver NASA’s Perseverance rover safely to Mars earlier this month, are also now being manufactured. Airborne Systems also supports the ground-based parachute extraction tests carried out at NASA/JPL.

- Unlike the one-parachute and sky-crane approach used by NASA’s Perseverance rover to land on Mars, the ESA-Roscosmos ExoMars mission requires two main parachutes – each with its own pilot chute for extraction – to help slow the descent module as it plunges through the atmosphere.

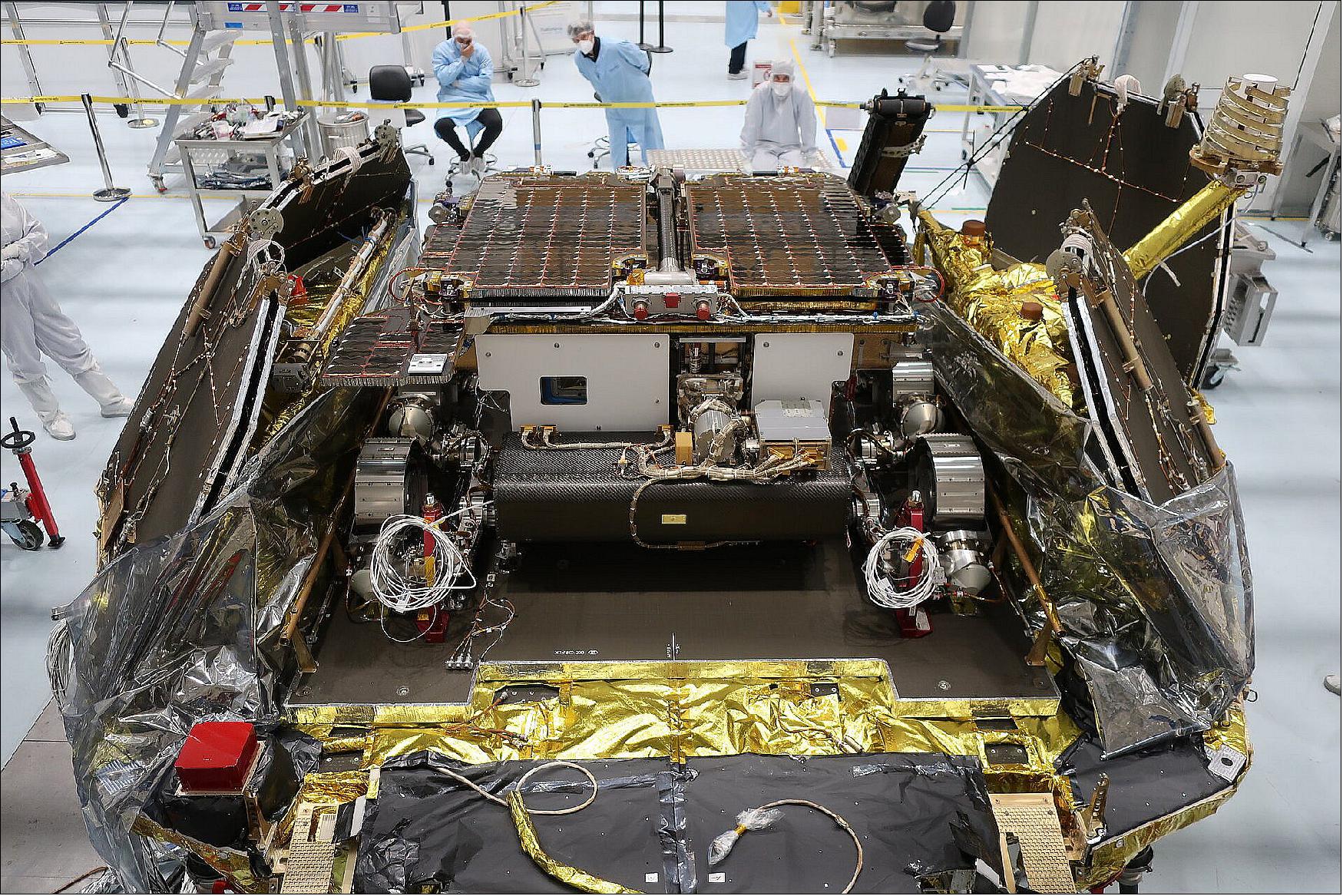

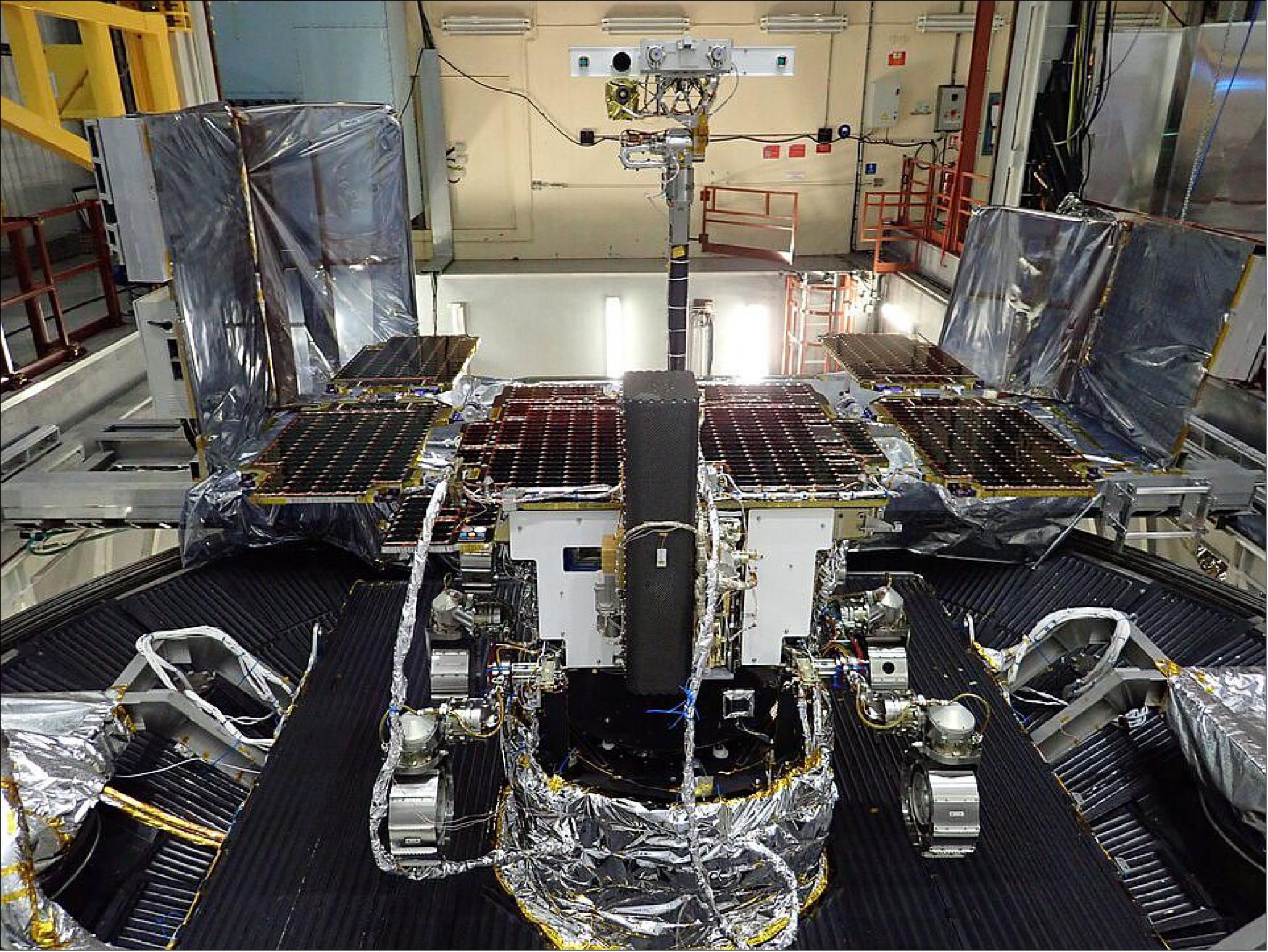

• December 8, 2020: The ExoMars Rosalind Franklin rover is seen here sitting on top of the Kazachok surface science platform in stowed configuration, rather similar to how it will journey to Mars in 2022. 24)

- The landing module will later be integrated inside the descent module for mass balancing checks, together with the carrier module that will transport the mission to Mars.

- This is not the last time the two flight models will be mated. After completion of the tests in Cannes, the rover will return to the TAS cleanrooms in Turin, Italy, for further functional testing, before being shipped to the launch site in Baikonur.

- In this image, the back right solar panel of the landing platform is seen partially deployed. The front of the rover is seen, with its iconic drill stowed in horizontal position. A first in Mars exploration, the drill will extract samples down to a maximum of two meters, where ancient biomarkers may still be preserved from the harsh radiation on the surface, and deliver them to the rover’s sophisticated laboratory for analysis.

- The mission aims to determine the geological history of the landing site at Oxia Planum, once thought to host an ancient ocean, and to determine if life could ever have existed on Mars.

- The ExoMars program is a joint endeavor between ESA and the Russian State Space Corporation, Roscosmos.

- The integration activities at Cannes were carried out by Thales Alenia Space and Airbus Defence and Space teams.

• November 18, 2020: The parachute system that will help deliver the Rosalind Franklin ExoMars rover to Mars has completed the first full-scale high altitude drop test with redesigned elements following two unsuccessful tests last year. Parachute extraction and deceleration proceeded as expected, the test vehicle landed safely and the test parachutes were recovered. However, some canopy damage occurred, pointing to the early inflation process for the focus of further improvements. 25)

- “Landing on Mars is extremely difficult, with no room for error,” says ExoMars Program Team Leader Francois Spoto. “The latest test was a good step forward but is not yet the perfect outcome we are seeking. Therefore, we will use the extensive test data we have acquired to refine our approach, plan further tests and keep on track for our launch in September 2022.”

Parachute Profile

- The Rosalind Franklin rover and Kazachok surface platform are encapsulated inside a descent module that will be transported to Mars by a carrier module. The descent module is equipped with two parachutes – each with its own pilot chute for extraction – to help slow it down prior to landing on Mars. Once the atmospheric drag has slowed the descent module from around 21 000 km/h to 1700 km/h, the first parachute will be deployed. Some 20 seconds later, at about 400 km/h, the second parachute will open. Following separation of the parachutes about 1 km above ground the braking engines will kick in to safely deliver the landing platform onto the surface of Mars. The entire sequence from atmospheric entry to landing takes just six minutes.

- The complete parachute descent system needs testing and verifying on Earth, for which high altitude drop tests play an essential role to help represent the low atmospheric pressure on Mars – a vital aspect when considering parachute inflation.

New Round of High Altitude Tests

- The test conducted from Oregon, USA was delayed from March 2020 due to COVID-19 restrictions, forest fires and unfavorable wind conditions. Logistics re-planning and compatible weather finally enabled it to take place 9 November.

- The test setup saw the drop test vehicle lofted to a height of 29 km in a stratospheric balloon.

- The first main parachute had an upgraded parachute bag and a Kevlar reinforcement around the vent hem (that is, around the vent 'hole' in the center of the parachute). The second main parachute had several reinforcement rings and an upgraded parachute bag, but not reinforced parachute lines, which are also planned. The fully upgraded second parachute will be used in a drop test at the Swedish Space Corporation ESRANGE facility in Kiruna, Sweden in mid-2021. The reinforcement rings were introduced to help prevent the dramatic tearing of the canopies witnessed during tests in 2019.

- The timeline of the latest test, including extraction and deceleration, went exactly to plan. However, four tears in the canopy of the first main parachute and one in the second main parachute were found after recovery. The damage seemed to happen at the onset of the inflation, with the descent otherwise occurring nominally.

- The team are now analyzing the test data to determine further improvements for the next tests. Planning is underway for future tests in the first half of next year, to ‘qualify’ the complete parachute system ready for launch in September 2022.

- Once safely in the Oxia Planum region of Mars in June 2023, the Rosalind Franklin rover will drive off the platform and begin its science mission. It will seek out geologically interesting sites to drill below the surface, to determine if life ever existed on our neighbor planet.

- All parachute system qualification activities are managed and conducted by a joint team involving the ESA, TASinI (prime contractor), TASinF (PAS lead), Vorticity (parachute design and test analysis) and Arescosmo (parachute and bags manufacturing).

- The ExoMars program is a joint endeavor between ESA and Roscosmos. In addition to the 2022 mission, it also includes the Trace Gas Orbiter (TGO) launched in 2016. The TGO is already both delivering important scientific results of its own and relaying data from NASA’s Curiosity Mars rover and InSight lander. It will also relay the data from the ExoMars 2022 mission once it arrives at Mars in 2023.

• November 4, 2020: ExoMars platform and rear jacket. 26)

• September 29, 2020: Last Sunday night a long, heavy truck hit the road escorted from Italy with a precious cargo. While most of the citizens in Turin prepared to enjoy their dinner, several modules of the ExoMars spacecraft left the Thales Alenia Space facilities. Next stop: Cannes, France. 27)

- The journey took less than a day. Besides stringent controls in dedicated clean rooms and tents – amongst the cleanest places on Earth – to avoid any biological contamination from Earth to Mars, Russian and European teams took a number of precautionary measures to minimize the risk of spreading the Coronavirus.

- Workers remained fully shrouded within ‘bunny suits’ to control any kind of contamination during the packing of the ExoMars elements before shipment. In this image, two engineers work on ESA’s Rosalind Franklin rover with its solar panels and drill folded.

- The microbiological samples taken after rigorous cleanliness procedures showed that the contamination levels were within the requirements for a safe landing on Mars.

- Engineers will be busy with a series of tests in the next months. The whole spacecraft will undergo thermal, vacuum and acoustic tests during the next months in France. Coming up is the deployment of the solar panels that will power up the Rosalind Franklin rover on Mars.

- Teleworking is nothing new to the ExoMars spacecraft and teams. There will be some remote operations in France before the year ends. Rosalind Franklin will be commanded from the Rover Operations Control Center (ROCC) at the ALTEC premises in Turin, Italy, to rehearse cruise and deployment maneuvers once on the surface of Mars.

- ExoMars leaves behind an intense period of testing in Italy since April, from health checks to assembly, maintenance operations and leak tests. Fasteners have been added to the solar panels of the rover to increase robustness during the unfolding and surface operations on the Red Planet.

- Rosalind Franklin is fitted with a drill – a first in Mars exploration – to extract samples down to a maximum of two meters, where ancient biomarkers may still be preserved from the harsh radiation on the surface, and hosts a sophisticated laboratory to analyze the samples on Mars.

- Both drill and laboratory have been extensively tested using soil similar to that expected on Mars and under conditions representative of the martian environment.

- The ExoMars program is a joint endeavor between ESA and the Russian State Space Corporation, Roscosmos.

• July 22, 2020: As Mars exploration prepares for a rebirth, a European rover tunes up its gear for the challenges ahead. 28)

- On 23 July, ESA and dozens of industrial partners will assess the readiness of the ExoMars robotic explorer, named Rosalind Franklin, for a trip to the Red Planet in 2022. The European rover will drill down to two meters into the martian surface to sample the soil, analyze its composition and search for evidence of life buried underground.

- The rover successfully proved that it is fit to endure the martian conditions during the environmental test campaign earlier this year in Toulouse, France. This laboratory on wheels withstood temperatures as low as –120°C and less than one hundredth of Earth’s atmospheric pressure to simulate the extremes of its journey through space and on the surface of Mars.

- By the end of this week a more robust set of solar panels will begin its trip to reunite with the rover after some cracks were detected during those environmental tests. New fasteners are in place and will be on their way from the Airbus facilities in Stevenage, in the UK, to Thales Alenia Space in Turin, Italy, where the rover awaits power up at the beginning of August.

- The disruptions caused by the coronavirus pandemic have added new obstacles for industry across Europe on the road to Mars. Parachute and interface tests are expected to resume in October.

- New missions to Mars launch from a broad range of nations – while the United Arab Emirates’ historic first mission to Mars lifted off from Japan last Sunday, China is preparing to launch tomorrow its first rover to Mars, known as Tianwen-1. NASA’s Mars 2020 mission is set to take off with the Perseverance rover onboard next week, on July 30.

- These missions focus on the search for evidence of life on the Red Planet and a better understanding of how Earth and Mars evolved so differently.

- “We hope that ESA’s Rosalind Franklin rover will help write a new page in Mars exploration by allowing us to study organic molecules on the spot,” says Jorge Vago, ESA’s ExoMars project scientist.

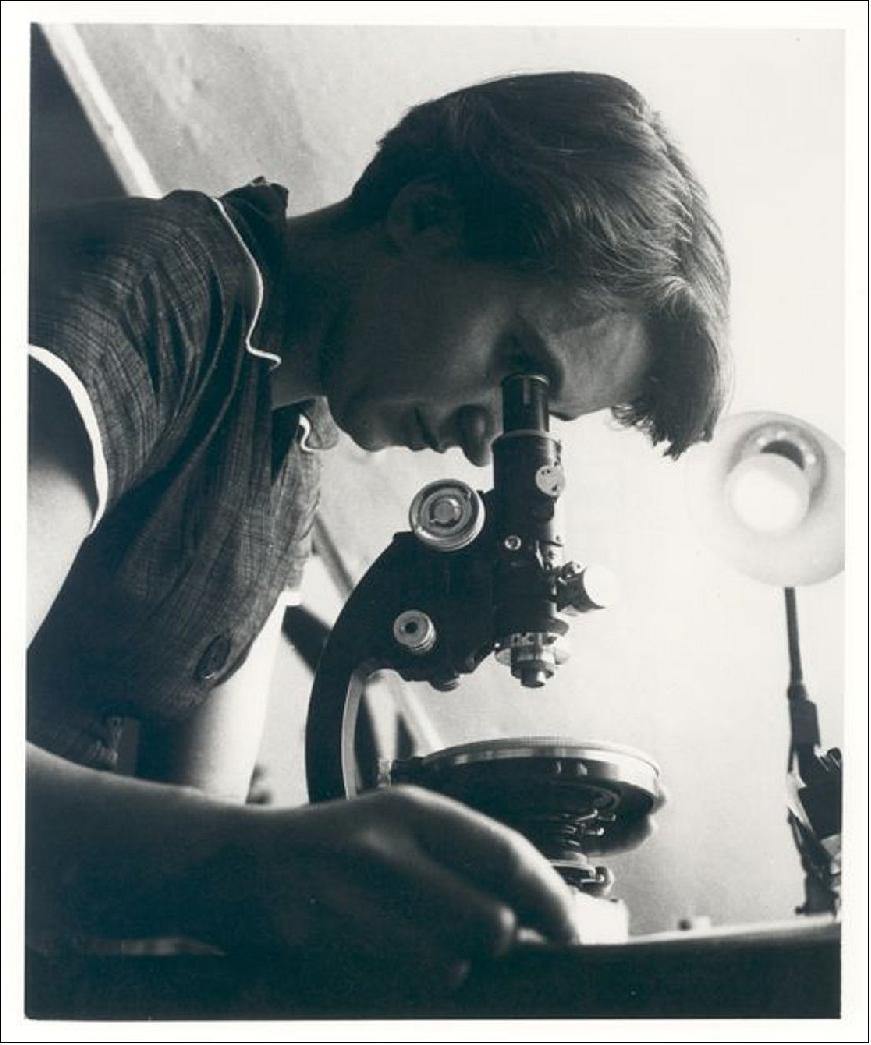

- Dr Rosalind Franklin, the prominent scientist behind the discovery of the structure of DNA, one of life’s most important molecules, would have been 100 years old on 25 July this year. Her niece, also named Rosalind Franklin in her memory, points out that the X-ray diffraction expert “never conceived science as a race of competitors.”

- After a visit to ESA’s technical center in the Netherlands last year, Rosalind believes that her aunt would have loved the ExoMars team spirit. “The work of ESA engineers on the rover struck me – they really do it for the results, not for themselves. This is what Rosalind Franklin was all about: commitment and dedication to science,” said Rosalind from her home in California, US.

- A series of talks and events is taking place around the globe this week to celebrate the centenary of this “woman of integrity who went after scientific discovery for the betterment of humankind”, as her niece describes her. The legacy of the scientist lives on today, and the ExoMars rover will help leave her symbolic footprint on Mars in 2023.

• May 15, 2020: The second ExoMars mission is taking advantage of the extra time to upgrade some of the rover’s instruments and get ready for the next parachute high-altitude drop tests. 29)

- The new launch date on the horizon is allowing more margin for replacements and repairs to the ExoMars Rosalind Franklin rover.

- The solar panels that will help the rover survive the cold Martian nights will gain in strength. After some cracks were detected during the environmental tests earlier this year, new fasteners will be installed to reinforce the interface between panels and holding brackets at the Airbus facilities in Stevenage, in the UK.

- The flight model of the rover remains at Thales Alenia Space in Turin, Italy, for routine maintenance operations, such as battery charge and cleanliness checks.

- Strict microbiological controls are key to make sure that ExoMars does not introduce terrestrial contamination to the Red Planet. This is to comply with the stringent planetary protection requirements and to avoid false positives in the scientific measurements – what scientists call ‘forward contamination’.

- Scientists and engineers are looking into replacing the secondary electronics box on the Mars Organic Molecule Analyzer, MOMA, an instrument capable of detecting organic molecules and investigate the potential origin, evolution and distribution of life on Mars.

- The infrared spectrometer that will analyze minerals on the surface, ISEM, might also be replaced with a spare model with better performance.

- One of the cameras on top of the rover’s drill designed to acquire high-resolution and color images of the rocks and soil around the rover – the Close-Up Imager, CLUPI – is having a software upgrade.

- “The instruments were already in great shape, but having found the time to make these improvements is fantastic for our scientific mission on Mars,” says Jorge Vago, ESA’s ExoMars project scientist.

Parachutes Ready for Drop Tests

- New deployment bags for the parachutes of the ExoMars mission are cleared to go for final high-altitude drop tests. However, travel restrictions in response to the coronavirus pandemic have forced to postpone these tests from May to September 2020 at the earliest.

- The dynamic extraction test campaign was a success. The updated design with eased lines and canopy exit proved to avoid tears at extraction velocities of 200 km/h, similar to the high speeds at which the parachutes will be pulled from their bags during the descent towards the surface of Mars.

- “The meticulous folding of each parachute inside its bag is essential to guarantee a correct deployment,” explains Thierry Blancquaert, ExoMars spacecraft systems engineering team leader.

- Just the folding of the second main parachute, which with 35 m of diameter will be the largest to ever fly on Mars, takes over three days.

- A total of six ground-based tests saw the clean extraction of the parachutes from their bags, with no frictional damage, during a test campaign between November 2019 and January 2020 at NASA’s Jet Propulsion Laboratory in California, US.

- These tests followed the high-altitude drop tests in 2019, during which critical damage to both parachute canopies was observed.

- The two parachutes – each with its own pilot chute for extraction – are key to slow the ExoMars descent module before landing on the Red Planet. In just six minutes, the module goes from around 21,000 km/h during atmospheric entry to a soft landing at the surface.

Flawless Release

- The high-speed tests mimicked the extraction velocity the parachutes will experience during the descent phase, just a couple of minutes before touchdown. A compressed air cannon shot the bag horizontally, releasing the parachute as it will happen during the mission.

- “The extraction takes a split second, it all happens very quickly,” says Thierry.

- ESA benefitted from NASA’s hands-on parachute experience. The cooperation gave Europe access to special test equipment at the Jet Propulsion Laboratory, and the opportunity to run several dynamic extraction tests on a quick turnaround.

- “It was a real challenge to organize this campaign so quickly with all the industry partners involved. The support provided by NASA was excellent and instrumental to the successful validation of our new parachute deployment bags,” adds Thierry.

Flying Higher

- The next step, high-altitude drop tests at a test range in Oregon, US, will have to wait until the end of September 2020. This type of tests requires complex logistics and strict weather conditions for flight safety.

- The test parachute embedded into its canister and mounted onto a drop test vehicle will be lifted to an altitude of nearly 30 km with a stratospheric helium balloon. This drop test vehicle will be released by telecommand and freefall until the test parachute sequence starts in pressure conditions similar to diving into the thin martian atmosphere.

- These tests should demonstrate the capability of the main parachutes to deploy smoothly from their bags and to sustain the inflation loads without tearing.

• April 2, 2020: Carefully wrapped inside this donut-shaped bag is a 35-m diameter parachute that will endure a frenzied six-minute dive into martian atmosphere. 30)

- The 64 kg parachute, made mostly of nylon and Kevlar fabrics, has been thoroughly sterilized to reduce its level of contamination for planetary protection. One of the main goals of ExoMars is to search for signs of life on the Red Planet, so any microbes hitchhiking on its ride from Earth would interfere with the investigation and could trigger a false positive – what scientists call ‘forward contamination’.

- The potential existence of past and perhaps even present life on Mars requires rigorous sterilization. Scientists want to be sure that the instruments on the ExoMars rover Rosalind Franklin, only detect signs of indigenous life, but protecting the martian environment from ourselves is equally as important. A planetary protection policy by the Committee on Space Research (COSPAR) details all requirements, in compliance with the United Nations Outer Space Treaty.

- The parachute was heated in an oven at 125°C for several days to kill any microbes. The oven is part of ESA’s Life, Physical Sciences and Life Support Laboratory, a state-of-the-art facility in the Netherlands. The Laboratory has also cleaned ExoMars instruments and subsystems, but this second stage parachute is the largest item to be sterilized.

- The dry heat sterilizer is in the ‘ISO Class 1’ cleanroom, one of the cleanest places in Europe. All air passes through a two-stage filter ensuring less than 10 dust particles no larger than 10 millionth of a meter, or less than the size of the coronavirus.

- People working on the ExoMars hardware are the main biohazard. Every day, each of us sheds millions of skin particles. Everyone entering the chamber has to gown up more rigorously than a surgeon before passing through an air shower to remove any remaining contaminants. Watch how to dress to avoid being a ‘bioburden’ in the latest ExoMars vlog.

- The parachute will next prove itself in high-altitude drop tests. The whole parachute assembly system, mounted onto a drop test vehicle, will be lifted to an altitude of nearly 30 km by helium balloon. The vehicle will free-fall until the test parachute sequence starts in pressure conditions similar to diving into the martian atmosphere.

- The dates of these tests have been postponed due to the coronavirus outbreak, and a new window of opportunity for testing is pending confirmation.

• March 12, 2020: The joint ESA-Roscosmos project team evaluated all the activities needed for an authorization to launch, in order to analyze the risks and schedule. With due consideration of the recommendations provided by European and Russian Inspectors General, ExoMars experts have concluded that tests necessary to make all components of the spacecraft fit for the Mars adventure need more time to complete. 31)

- The primary goal of the mission is to determine if there has ever been life on Mars, and to better understand the history of water on the planet. The ExoMars rover, named Rosalind Franklin, includes a drill to access the sub-surface of Mars as well as a miniature life-search laboratory kept within an ultra-clean zone.

- In the frame of a dedicated meeting, ESA and Roscosmos heads Jan Wörner and Dmitry Rogozin agreed that further tests to the spacecraft with the final hardware and software are needed. In addition, the parties had to recognize that the final phase of ExoMars activities are compromised by the general aggravation of the epidemiological situation in European countries.

- "We have made a difficult but well-weighed decision to postpone the launch to 2022. It is driven primarily by the need to maximize the robustness of all ExoMars systems as well as force majeure circumstances related to exacerbation of the epidemiological situation in Europe which left our experts practically no possibility to proceed with travels to partner industries. I am confident that the steps that we and our European colleagues are taking to ensure mission success will be justified and will unquestionably bring solely positive results for the mission implementation," said Roscosmos Director General Dmitry Rogozin.

- "We want to make ourselves 100% sure of a successful mission. We cannot allow ourselves any margin of error. More verification activities will ensure a safe trip and the best scientific results on Mars,” said ESA Director General Jan Wörner.

- "I want to thank the teams in industry that have been working around the clock for nearly a year to complete assembly and environmental testing of the whole spacecraft. We are very much satisfied of the work that has gone into making a unique project a reality and we have a solid body of knowledge to complete the remaining work as quickly as possible."

- To date, all flight hardware needed for the launch of ExoMars has been integrated in the spacecraft. The Kazachok landing platform is fully equipped with thirteen scientific instruments, and the Rosalind Franklin rover with its nine instruments recently passed final thermal and vacuum tests in France.

- The latest ExoMars parachutes dynamic extraction tests have been completed successfully at NASA’s Jet Propulsion Laboratory, and the main parachutes are ready for the two final high-altitude drop tests in March in Oregon, US.

- The descent module has been undergoing propulsion system qualification in the past month. The ExoMars descent module and landing platform have been undergoing environmental testing in Cannes, France, to confirm the spacecraft is ready to endure the harsh conditions of space on its journey to Mars.

- ExoMars will be the first mission to search for signs of life at depths up to two meters below the martian surface, where biological signatures of life may be uniquely well preserved.

• February 14, 2020: The Rosalind Franklin ExoMars rover after completing environmental and vacuum testing in Toulouse, France. The rover was tested in a clean room to withstand conditions similar to those on Mars. 32)

- The ExoMars rover will be Europe’s first planetary rover. It will search for signs of past or present life on Mars and is equipped with a 2m drill to take samples from below the surface where they will have been protected from the harsh radiation environment.

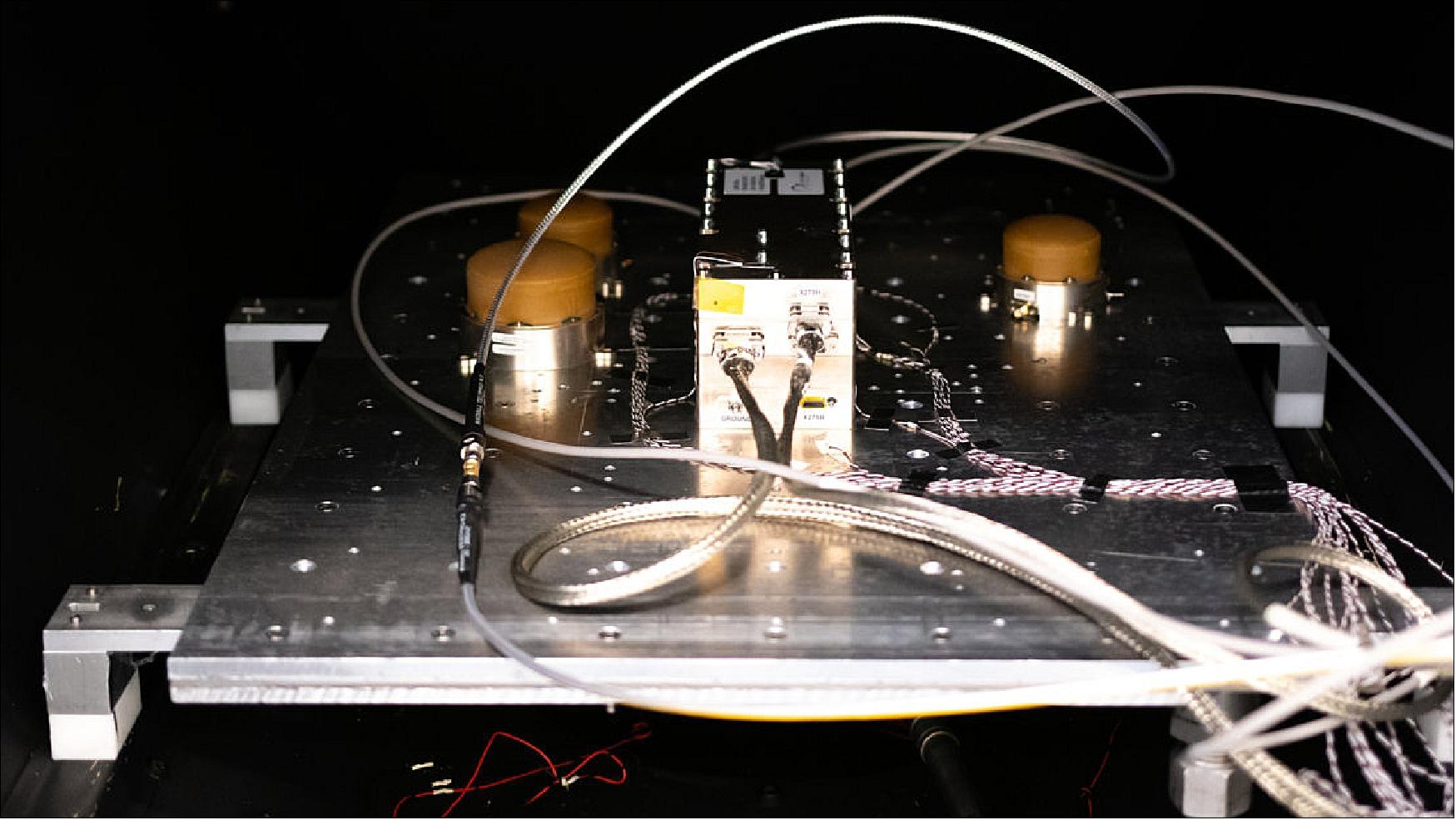

• February 13, 2020: The ExoMars landing platform, carrier and descent modules together during environmental testing in the anechoic chamber at Thales Alenia Space (TAS) in Cannes, France. 33)

- The composite spacecraft is undergoing environmental testing to confirm it is ready to endure the harsh conditions of space on its eight-month journey to Mars.

- The three integrated modules were placed in a special chamber with the inside walls covered with pyramid-shaped non-reflective foam to absorb signals such as TV and radio, radar and even mobile phone calls, and prevent unwanted reflections.

- The tests will verify that the modules work well together without any glitches or interference.

- The ExoMars mission will investigate how Mars has evolved and whether there may be conditions for life.

• January 16, 2020: The Rosalind Franklin rover of the joint ESA-Roscosmos ExoMars mission completed a series of environmental tests at the end of 2019 at Airbus, Toulouse, France. This included final thermal and vacuum tests where the Rover is heated and cooled to simulate the temperatures of its journey through space and on the surface of Mars. For example, Rosalind Franklin can expect temperatures dropping to –120°C outside, and –50 °C inside the rover once on Mars. It must also be able to operate in less than one hundredth of Earth’s atmospheric pressure – and in a carbon dioxide-rich atmosphere. 34)

- Last year the ‘structural and thermal model’ of the rover successfully completed a rigorous environmental test campaign; the latest round of tests subjected the real flight-model to the simulated space environment.

- Now the focus moves to final checks on the rover systems. This includes checking the alignment of instruments working together, such as the imaging systems, and a final functional test of the integrated system after the environmental campaign. Once these verifications on the rover are completed, a functional check of the interfaces with the surface platform and descent module that will deliver it safely to the surface of Mars will be performed at Thales Alenia Space, Cannes, France.

- The primary goal of the mission is to determine if there is or there has ever been life on Mars, and to better understand the history of water on the planet. The rover will seek out interesting geological locations to examine with its scientific tools and to drill to retrieve underground samples, on a quest to tackle these questions.

• December 19, 2019: A series of ground-based tests designed to check the extraction of the ExoMars 2020 mission’s parachutes from their bags have started successfully with promising results to keep the mission on track for next year’s launch. 35)

- Landing on Mars is a high-risk endeavour with no room for error. In just six minutes, a descent module with its precious cargo cocooned inside has to slow from around 21,000 km/h at the top of the planet’s atmosphere, to a soft landing at the surface controlled by the lander’s propulsion system.

- A key element of reaching the surface safely is based around a parachute system.

- For ExoMars 2020, which comprises the Rosalind Franklin rover to explore the planet for signs of life, and the Kazachok surface platform to monitor the local environment at the landing site, a two-parachute system is used, each with its own pilot chute for extraction. The first main parachute has a diameter of 15 m and will be deployed while the descent module is still travelling at supersonic speeds, while the second main parachute has a 35 m diameter, the largest to ever fly on Mars.